Fillet Weld Size Chart

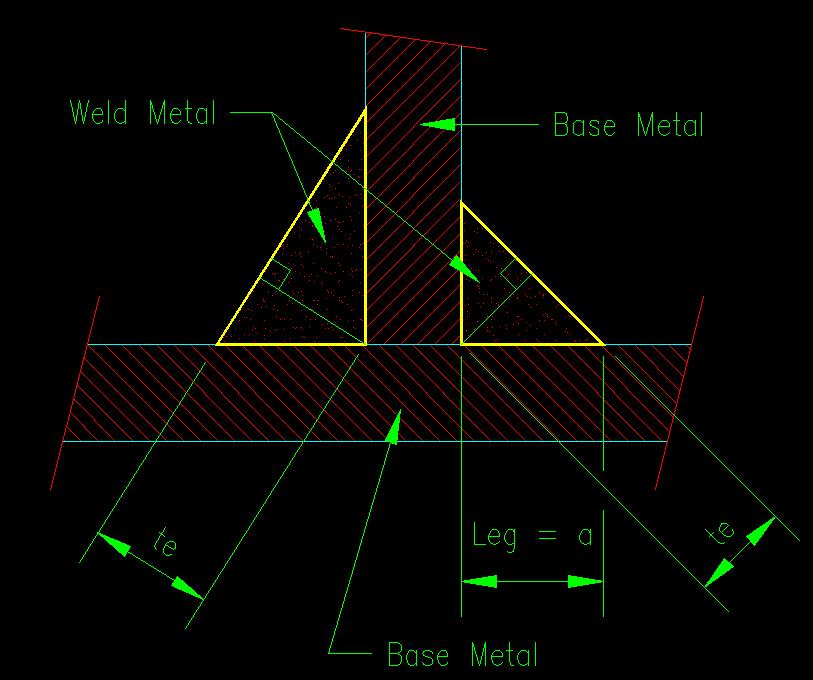

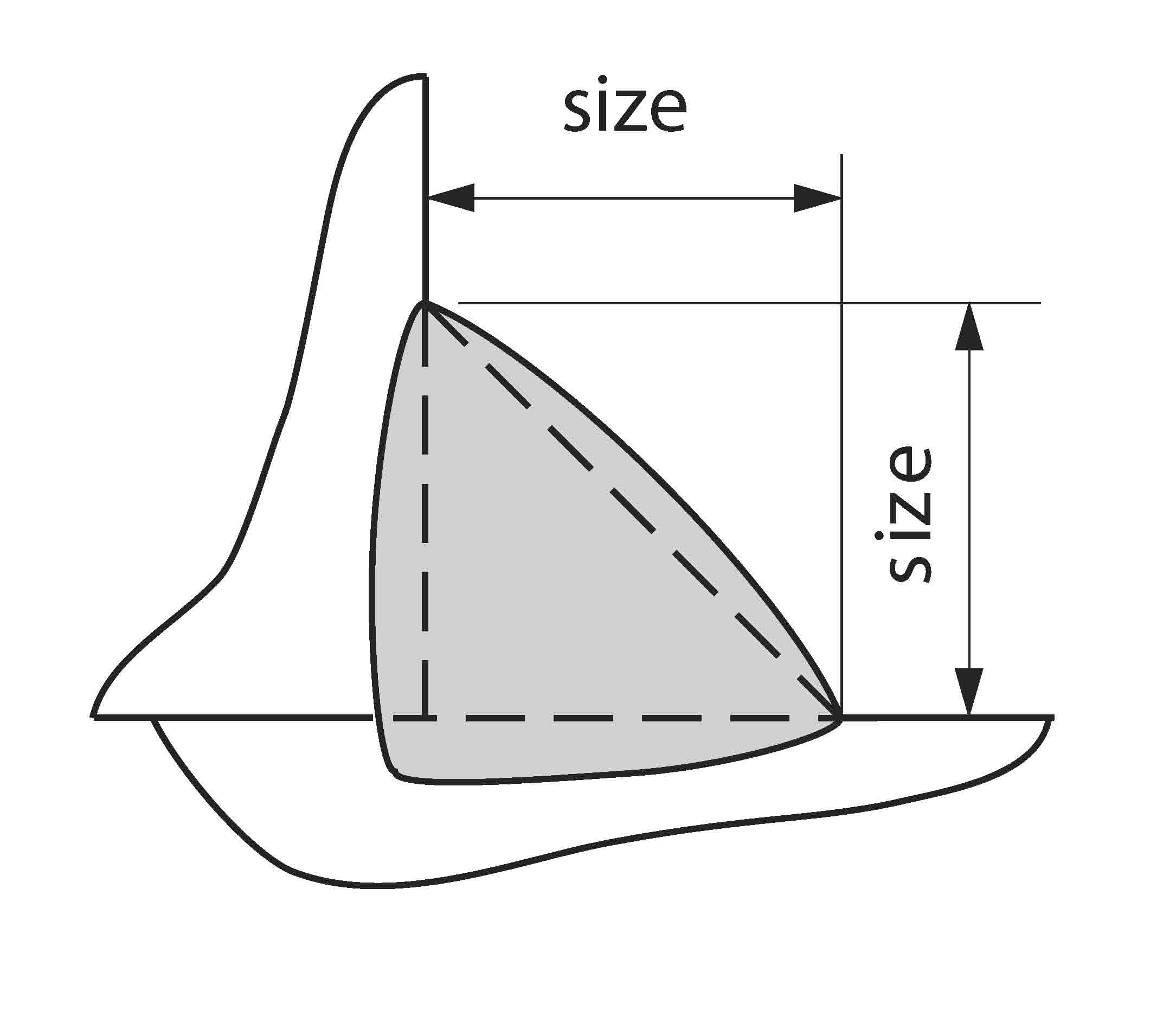

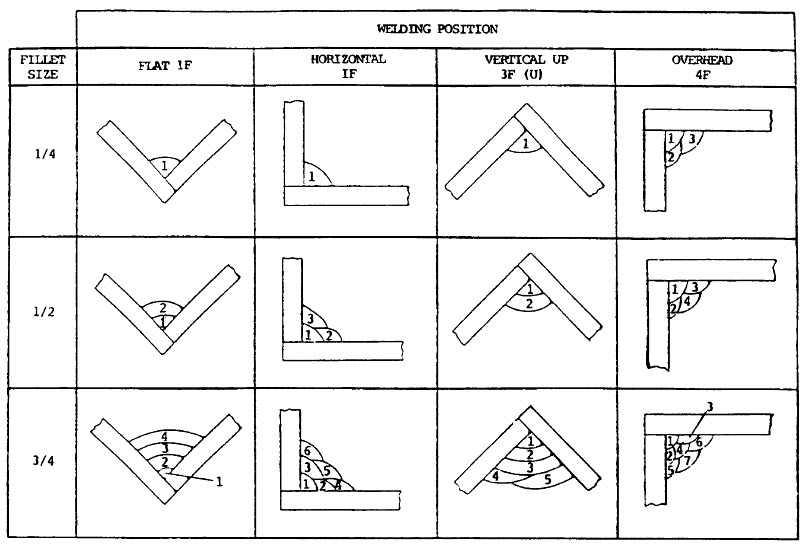

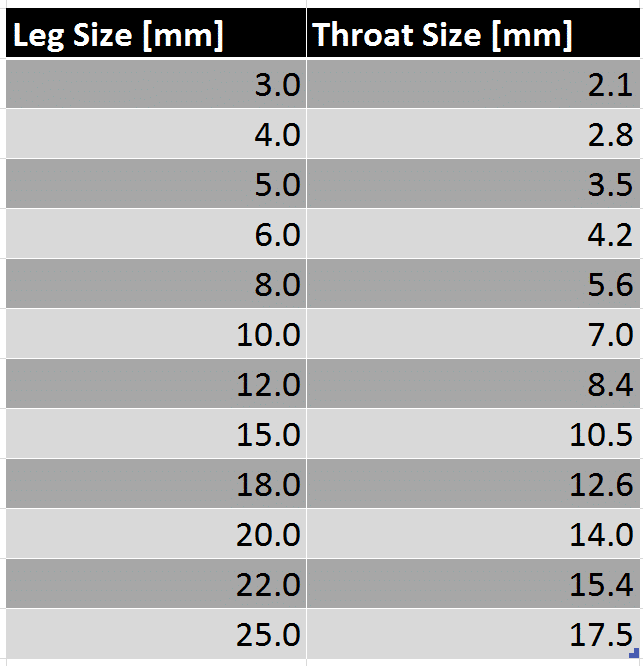

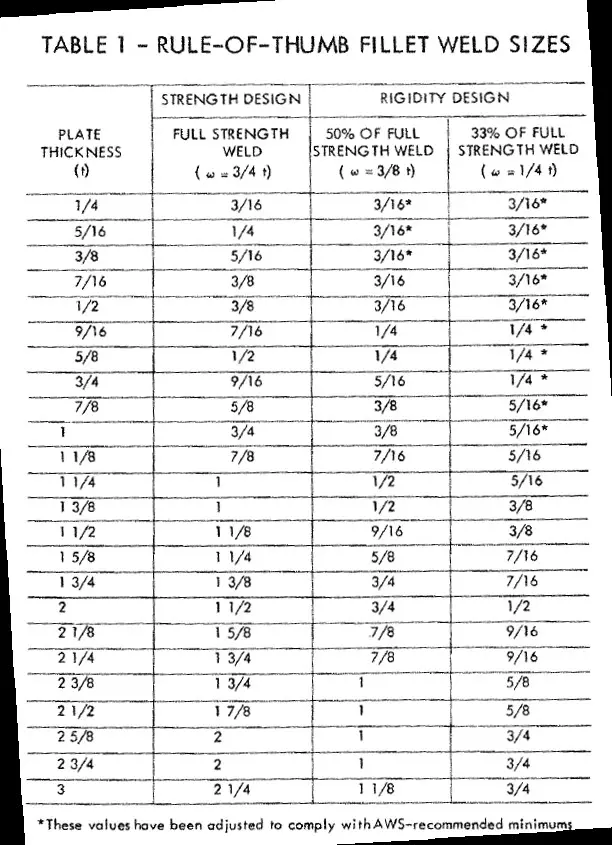

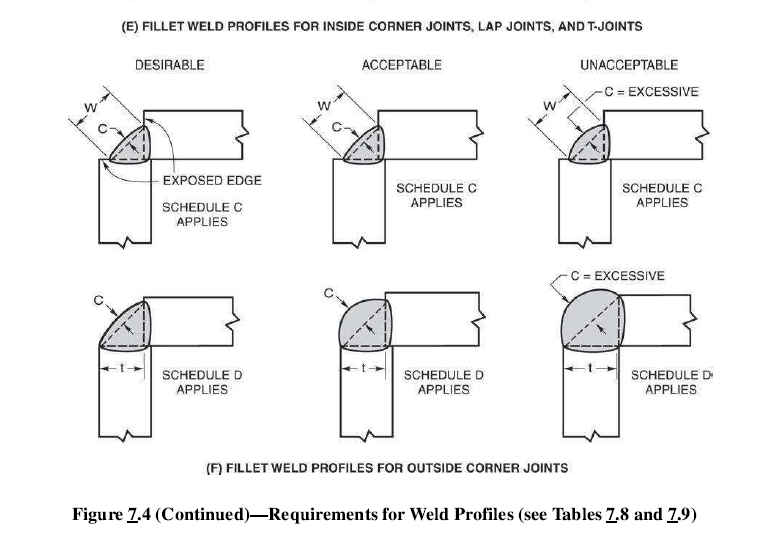

Fillet Weld Size Chart - Allowable reduction in throat convexity. No increase in the effective area for design calculations is permitted for weld reinforcement. If this limit is exceeded. This means that exceeding the size specified would increase weld strength, but not the connection strength. Web (1) the size of an equal leg fillet weld is the leg length of the largest inscribed right isosceles triangle. International standards do not generally provide requirements or guidance on minimum fillet weld sizes. Web thus, setting the fillet weld strength equal to the controlling plate strength, we find the following weld leg size required: Theoretical throat = 0.7 × size of weld. The fillet weld size will be the optimum weld size using this calculation and fits. The maximum size of the fillet weld will be= 0.7 x t, where ‘t’ is the base metal thickness. Web the weld size of a complete joint penetration groove weld shall be the thickness of the thinner part joined. This section will cover the process of calculating fillet weld sizes and the importance of reporting them accurately. Fillet weld is specified by a size known as either throat size (given as a) or leg length (given as z). The. Common joint designs for fillet welds. Leg length of a fillet weld, Recommended weld profile in aws. And as allowed by tables 7.8, 7.9, 8.1 , and 10.15. First let’s go through a few items regarding this rule of thumb. (2) the size of an unequal leg fillet weld is the shorter leg length of the largest right triangle that can be inscribed within the fillet weld cross section. Web this post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. Fillet weld is specified by a size known. This is one of the most common terms related to welding for joining two metal pieces together to get a permanent joint. (2) the size of an unequal leg fillet weld is the shorter leg length of the largest right triangle that can be inscribed within the fillet weld cross section. Over specified fillet welds or oversized fillet welds. Without. Web the size of an equal leg fillet weld is the leg length of the largest inscribed right isosceles triangle. S = deep penetration throat thickness. Web written by anup kumar dey in construction. Maximum size of fillet weld. The maximum size of the fillet weld will be= 0.7 x t, where ‘t’ is the base metal thickness. The fillet weld size will be the optimum weld size using this calculation and fits. Meaning welding anything bigger would be total waste with no added benefits. Leg length of a fillet weld, Each path is explained in further detail later in this article; Web (1) the size of an equal leg fillet weld is the leg length of the. Min (0.3 fu t, 0.4 fy t) = 29.7 w therefore, the required weld leg size is the lesser of 0.3 fu t /29.7 and 0.4 fy t /29.7. Web the faces of fillet welds may be slightly convex, flat, or slightly concave as shown in figure 7.4. The fillet weld size will be the optimum weld size using this. The joint preparation and welding process(es) are then determined by the production unit in order to meet the specified requirements. Fillet weld convexity or concavity. This means that exceeding the size specified would increase weld strength, but not the connection strength. This is one of the most common terms related to welding for joining two metal pieces together to get. Web weld sizes should be determined based on structural requiremnts and specified. Meaning welding anything bigger would be total waste with no added benefits. Theoretical throat = 0.7 × size of weld. Dimension of a fillet weld. Maximum size of fillet weld. Web the selection of fillet size in both aws d1.1 and aws d1.2 involves specific guidelines and considerations tailored to the respective standards and the materials being used. Web a fillet weld symbol can be used with an arrow side (below reference line) other side (above reference line) significance or on both sides (both sides of the reference line.) when. Web accurately determining the size of a fillet weld is crucial for ensuring the structural integrity and performance of welded components. Leg length of a fillet weld, Maximum size of fillet weld. Web the selection of fillet size in both aws d1.1 and aws d1.2 involves specific guidelines and considerations tailored to the respective standards and the materials being used. S = deep penetration throat thickness. Web the aws defines a fillet weld as: Web the faces of fillet welds may be slightly convex, flat, or slightly concave as shown in figure 7.4. Web this post gives simple calculations for determining the minimum and maximum fillet weld sizes to withstand the maximum stresses at the weld. Web drawings by specifying essential design information such as weld dimensions, quality level, etc. Web built with convertkit. If this limit is exceeded. 2.4 fillet welds 2.4.1 effective throat Without correction, provided that the undersize portion of the weld does not exceed 10% of the length of the weld. Dimension of a fillet weld. Web the size of an equal leg fillet weld is the leg length of the largest inscribed right isosceles triangle. Web the aws d 1.1 (structural welding code ― steel) code, table 7.7 (given below) specifies the minimum fillet weld size for each base material thickness.

6 Calculation of fillet weld strength Download Table

How It Works How do you determine the adequate size of a fillet weld

Effective Area & Size

Minimum Size of Fillet Welds CISCICCA

fillet weld size chart Car Tuning

FAQ Jensen Consulting CAD Services

Rule Of Thumb For determining the Fillet Weld Size

Fillet Weld Size Chart

Fillet Weld Sizing Guidelines OnestopNDT

Fillet weld in lap joint IDEA StatiCa

Web Traditionally, Fillet Weld Size Is Based Upon The Thickness Of The “Weaker” Member And Two Mechanical Properties, The Ultimate Tensile Strength Of The Base Material, And The Longitudinal Shear Strength Of The Weld Material.

Web Thus, Setting The Fillet Weld Strength Equal To The Controlling Plate Strength, We Find The Following Weld Leg Size Required:

Each Path Is Explained In Further Detail Later In This Article;

Bs En Iso 2553 Uses The Following Notation As Figs.

Related Post: