Engine Turning Patterns

Engine Turning Patterns - [1] [2] traditionally, engine turning referred to guilloché engraving. For the rest of this document, i will use engine turning to mean the kind of pattern on the spirit of st. It is easily carried out in the home shop using simple materials. It involves the use of a specialized turning machine that rotates the metal piece while a cutting tool is applied to create the desired design. The beautiful patterns on the pieces in the image at the top of the page are made by engine turning, also referred to as jeweling. Web technical mastery combined with artistic expression. Here’s a motorcycle instrument pod done by reader nate: In this group of videos he describes the use of the rose eng. Web watchmaker roger smith describes the detailed techniques he uses to make a hand made watch dial. Web engine turning is a decorative process applied to metal. An interesting engine turning technique. It’s seen in a number of different applications. Engine turning is a process of inscribing geometric patterns onto metal surfaces as a finish. Engine turning is a process of inscribing geometric patterns onto metal surfaces as a finish. In this video i demonstrate severa. Web engine turning, also known as damascening, is a quintessential example of high quality auto metalworking. Web creating engine turning patterns with pcnc 1100 tormach & cratex abrasive stick. This is work done on a rose engine lathe, and is often done on high end watches. The circular swirls create an amazing holographic, 3d optical effect as you walk past. Engine turning, or jeweling, or guilloché, or a whole host of other names, is the art of polishing a pattern of circles on a piece of metal. The fruits of this craft, very nearly a lost art, can be found adorning all manner of watch parts including cases, dials and movements. 4 circles precisely arranged in an offset stacked pattern. Web to make it clear what kind of engine turning i am interested in, consider the image of the spirit of st. In this group of videos he describes the use of the rose eng. 4 circles precisely arranged in an offset stacked pattern creating the classic engine turn pattern. This is work done on a rose engine lathe, and. Web creating engine turning patterns with pcnc 1100 tormach & cratex abrasive stick. Web engine turning is an increasingly scarce mechanised engraving technique, which involves the use of a turning engine to cut intricate, repetitive patterns onto a metal surface. Engine turning can be used to enhance the appearance of. 4 circles precisely arranged in an offset stacked pattern creating. Engine turning, or jeweling, or guilloché, or a whole host of other names, is the art of polishing a pattern of circles on a piece of metal. One common example is the. Web a rose engine is used to turn and cut the patterns on a brass dial blank while the straight line engine creates the straight pattern often used. The beautiful patterns on the pieces in the image at the top of the page are made by engine turning, also referred to as jeweling. The fruits of this craft, very nearly a lost art, can be found adorning all manner of watch parts including cases, dials and movements. Engine turning is a process of inscribing geometric patterns onto metal. Making small dies with engine turned patterns by john moorhouse. At the peak of its popularity, engine turning was used to decorate compact mirrors, boxes, hairbrushes and watch cases and dials, before its widespread use began. So, lapping compound is something you’re most probably going to use at some point. Sheet metals include aluminum, stainless steel, and galvanized sheet. Web. You see it on fine watches, and you. How complicated radiating patterns are engraved in metal). Web engine turning is a decorative process applied to metal. Before tracing out the pattern on the steel, i wiped down the. Engine turning can be used to enhance the appearance of. One common example is the. Red dirt rodz brings you another quickie tech video! Here’s a motorcycle instrument pod done by reader nate: If you are interested in the other kind of engine turning, the kind done with a machine called a rose engine or decoration lathe. Web engine turning, is the process of adding unique swirl patterns on flat. Other thicknesses up to 7 gauge (3/16) are available. According to joshua shapiro, an american watchmaker who specialised in the guilloché, engine turning is the “process of using a sharp cutting tool to carve geometric patterns into metal”. In this video i demonstrate severa. [1] [2] traditionally, engine turning referred to guilloché engraving. Red dirt rodz brings you another quickie tech video! This is work done on a rose engine lathe, and is often done on high end watches. It is easily carried out in the home shop using simple materials. Not only beautiful, lending metals an almost holographic depth, turning distracts from normal soiling and is thought to make cleaning easier. Sheet metals include aluminum, stainless steel, and galvanized sheet. It’s seen in a number of different applications. At the peak of its popularity, engine turning was used to decorate compact mirrors, boxes, hairbrushes and watch cases and dials, before its widespread use began. How complicated radiating patterns are engraved in metal). Web watchmaker roger smith describes the detailed techniques he uses to make a hand made watch dial. Sheet thicknesses range from.030″ to 1/8″ thick. The fruits of this craft, very nearly a lost art, can be found adorning all manner of watch parts including cases, dials and movements. The society of ornamental turners bulletin.

Jon Sauer's Incredible Rose Engine Turning Patterns Core77

Jon Sauer's Incredible Rose Engine Turning Patterns Core77

Jon Sauer's Incredible Rose Engine Turning Patterns Core77

Jon Sauer's Incredible Rose Engine Turning Patterns

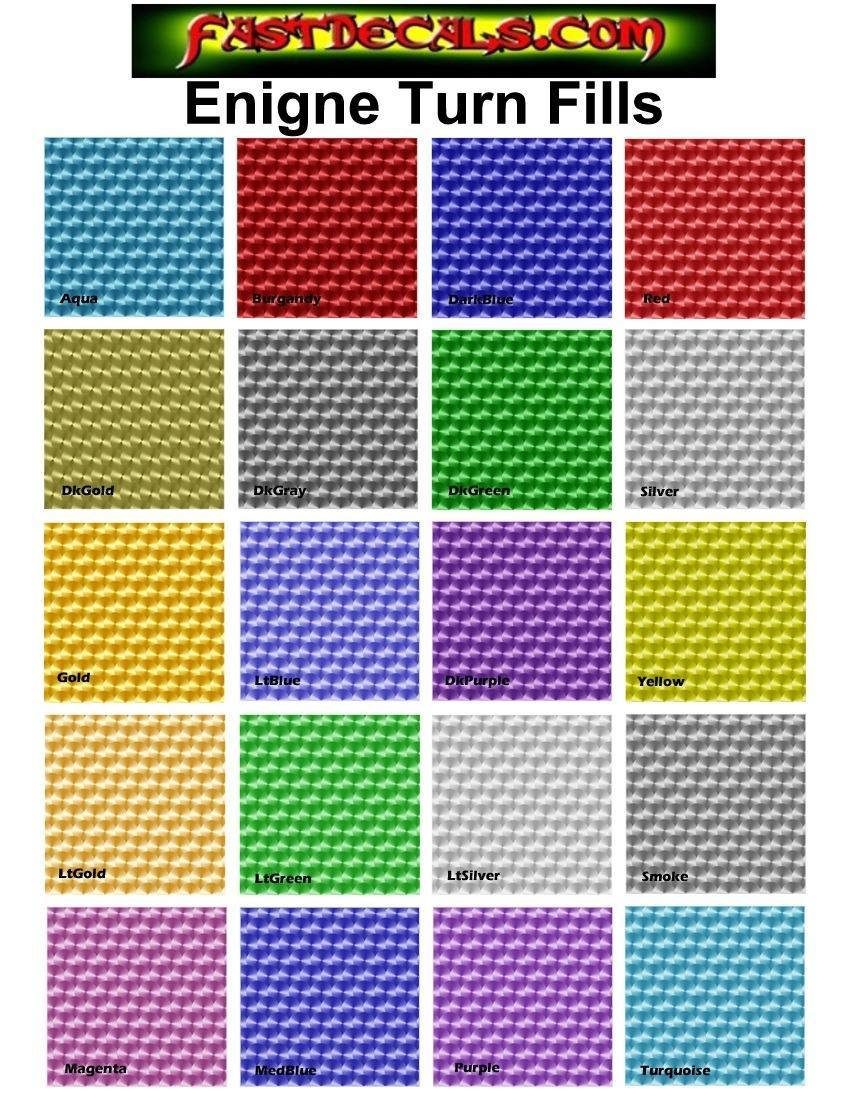

CUSTOM ENGINE TURNED DECALS and STICKERS

Jon Sauer's Incredible Rose Engine Turning Patterns — fazyluckers

Jon Sauer's Incredible Rose Engine Turning Patterns — fazyluckers

Jon Sauer's Incredible Rose Engine Turning Patterns — fazyluckers

Jon Sauer's Incredible Rose Engine Turning Patterns Core77

Jon Sauer's Incredible Rose Engine Turning Patterns — fazyluckers

Web My Friend Palmer Moynihan Is My Guest Instructor Today Demonstrating Engine Turning.

Web Engine Turning Is A Decorative Process Applied To Metal.

Standard Thicknesses Are 22 Gauge (.0293) And 16 Gauge (.0595).

Web Engine Turning, Also Referred To As Guilloché In French, Is Perhaps The Most Traditional Method Of Dial Finishing.

Related Post: