E Circlip Size Chart

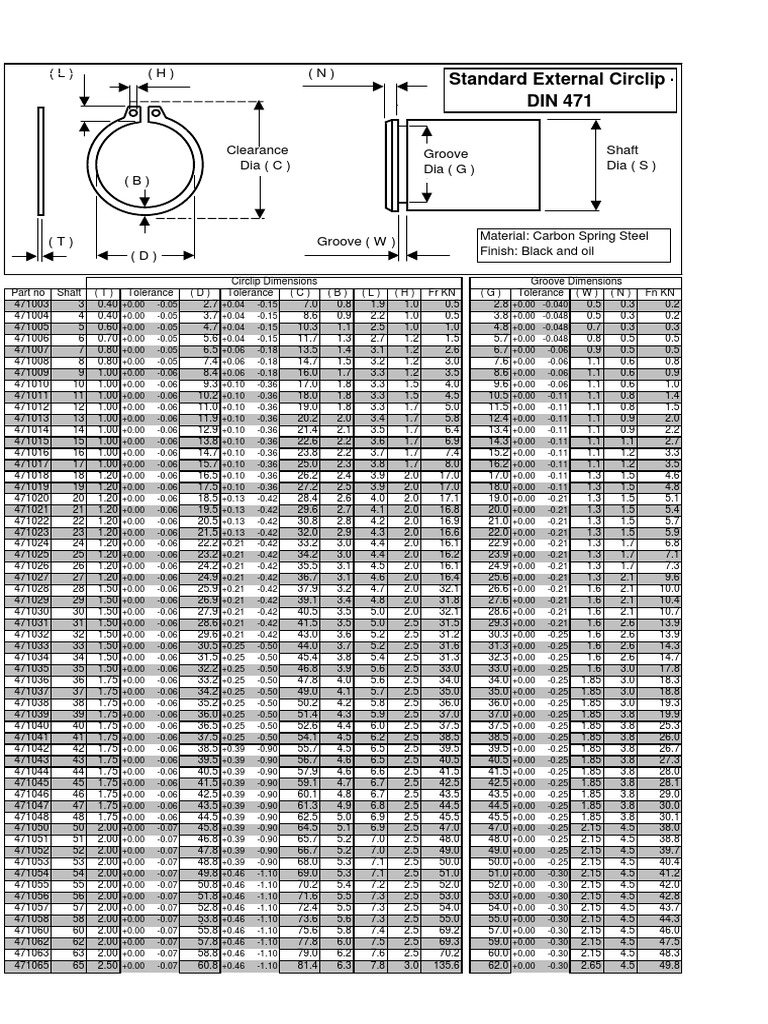

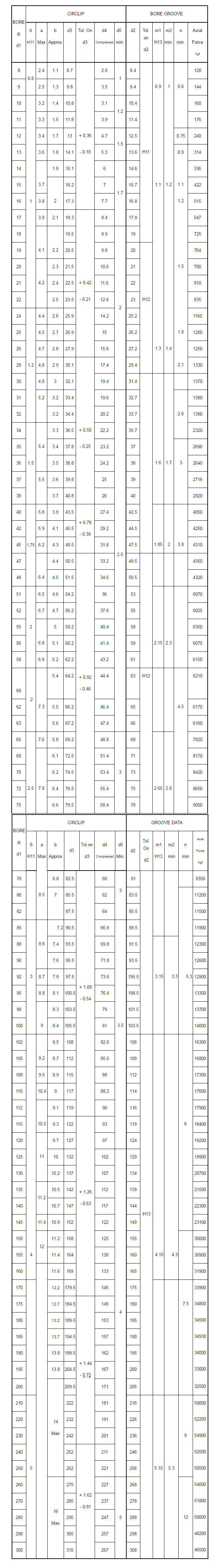

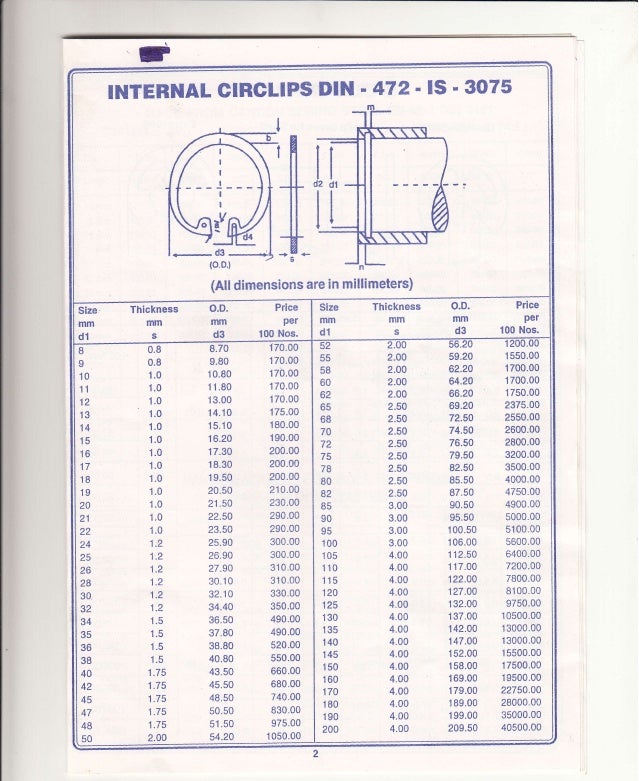

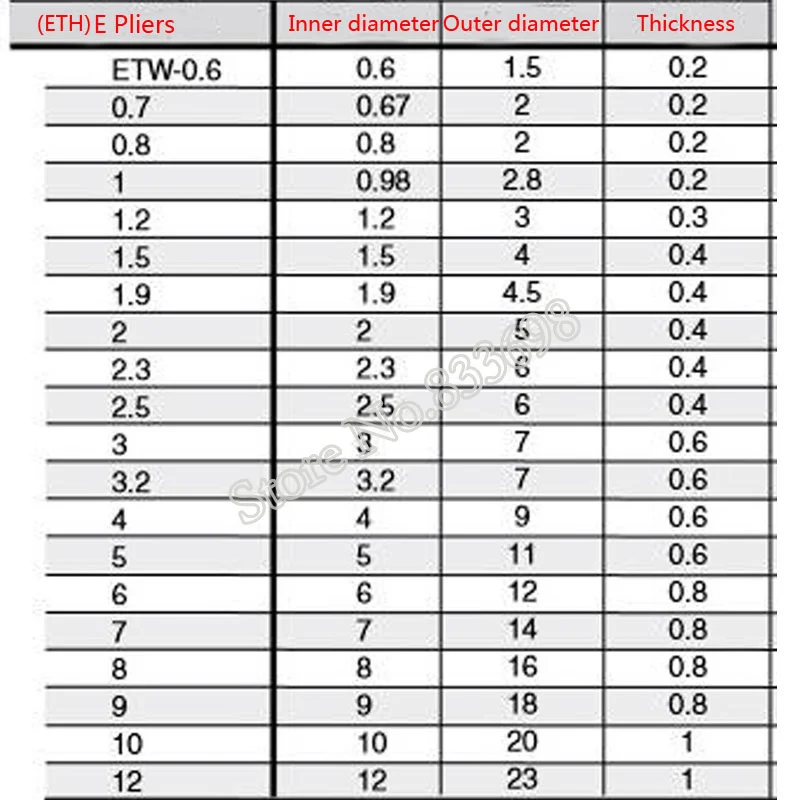

E Circlip Size Chart - They include only for sharp edges of stressed surfaces in contact with the circlips. Provide a large shoulder on a relatively small shaft diameter. Circlips generally to dimensions according to din 471. The most common form of radially fitted circlips for shafts with grooves. This range can be supplied stacked on rods for use with applicators and dispensers for rapid installation, thus resulting in sharply reduced assembly costs. Use these compact type e external circlips as an alternative to larger fastener assemblies by installing them tightly around shaft or bore elements. Here is a general guide and size chart for external and internal circlips: Web by matching the e clip size to the shaft and groove dimensions, you can ensure a secure fit and optimal performance. It is important you stick with the same unit of measurement so you get the right component. Circlips generally to dimensions according to din 471. Web see below for our circlip din 471 chart, which includes technical information such as circlip sizes, circlip groove dimensions, corresponding circlip pliers and more. The most common form of radially fitted circlips for shafts with grooves. They act as the retaining ring in bores and other applications in which radial and centrifugal force is applied to the assembly. Web. Circlips generally to dimensions according to din 471. Web the inside diameter of an external circlip measures 30mm. Is 3075, din 471 material: Web the dimensions of circlips can vary depending on the standard and size. (also available in stainless steel) E type circlips incorporating din 6799 and bs3673/2 metric series. Web provide a large shoulder on a relatively small shaft diameter. This range can be supplied stacked on rods for use with applicators and dispensers for rapid installation, thus resulting in sharply reduced assembly costs. Is 3075, din 471 material: Web see below for our circlip din 471 chart, which. The load capacities shown are for first estimate values for initial design evaluations. Provide a large shoulder on a relatively small shaft diameter. Arcon ring's internal metric circlip d1300 din 472 is available in a multitude of sizes. View our specification chart for a better fit and more information. Is 3075, din 471 material: (also available in stainless steel) Phosphating or as per requirements hardness: E type circlips incorporating din 6799 and bs3673/2 metric series. Web the dimensions of circlips can vary depending on the standard and size. Web provide a large shoulder on a relatively small shaft diameter. The load capacities shown are for first estimate values for initial design evaluations. Here is a general guide and size chart for external and internal circlips: The most common form of radially fitted circlips for shafts with grooves. This range can be supplied stacked on rods for use with applicators and dispensers for rapid installation, thus resulting in sharply reduced. Is 3075, din 471 material: Circlips generally to dimensions according to din 471. The most common form of radially fitted circlips for shafts with grooves. The load capacities shown are for first estimate values for initial design evaluations. Web provide a large shoulder on a relatively small shaft diameter. At caleb components we stock a wide range of imperial and metric fastening components including e clips. We can also offer these in a bright zinc plate or zinc/yellow finish. Web the dimensions of circlips can vary depending on the standard and size. Finish the installation by installing them over the shaft groove. The load capacities shown are for first. This range can be supplied stacked on. Is 3075, din 471 material: View our specification chart for a better fit and more information. Only the groove size is critical with this type of circlip, the shaft diameter can be varied widely. Carbon spring steel standard finish: 0.050 to 60 standard material: Web see below for our circlip din 471 chart, which includes technical information such as circlip sizes, circlip groove dimensions, corresponding circlip pliers and more. Circlips are fasteners that fit into the radial grooves of shafts and holes that are sprung to ensure they remain securely in place. Phosphating or as per requirements hardness: They. Our carbon spring steel metric circlips come in various sizes to meet your needs and adapts well to high rotational speeds. At caleb components we stock a wide range of imperial and metric fastening components including e clips. E type circlips incorporating din 6799 and bs3673/2 metric series. If you can’t find the size you’re looking for, please don’t hesitate to contact us so we can help you find what you need. The most common form of radially fitted circlips for shafts with grooves. Three prongs make contact with the bottom of the groove and provide a shoulder for effective retention of assemblies. Web see below for our circlip din 471 chart, which includes technical information such as circlip sizes, circlip groove dimensions, corresponding circlip pliers and more. The load capacities shown are for first estimate values for initial design evaluations. Calculate the dimensions of the groove on the bore. They act as the retaining ring in bores and other applications in which radial and centrifugal force is applied to the assembly. Carbon spring steel standard finish: The purpose of the e clips is to restrict the loosening of the components due to the rapid rotational motion. Web e clips and other fasteners are typically made in both sizes, measured in inches or millimetres. Provide a large shoulder on a relatively small shaft diameter. 0.050 to 60 standard material: Web e type circlips incorporating din 6799 and bs3637/2 metric series the most common form of radially fitted circlips for shafts with grooves.

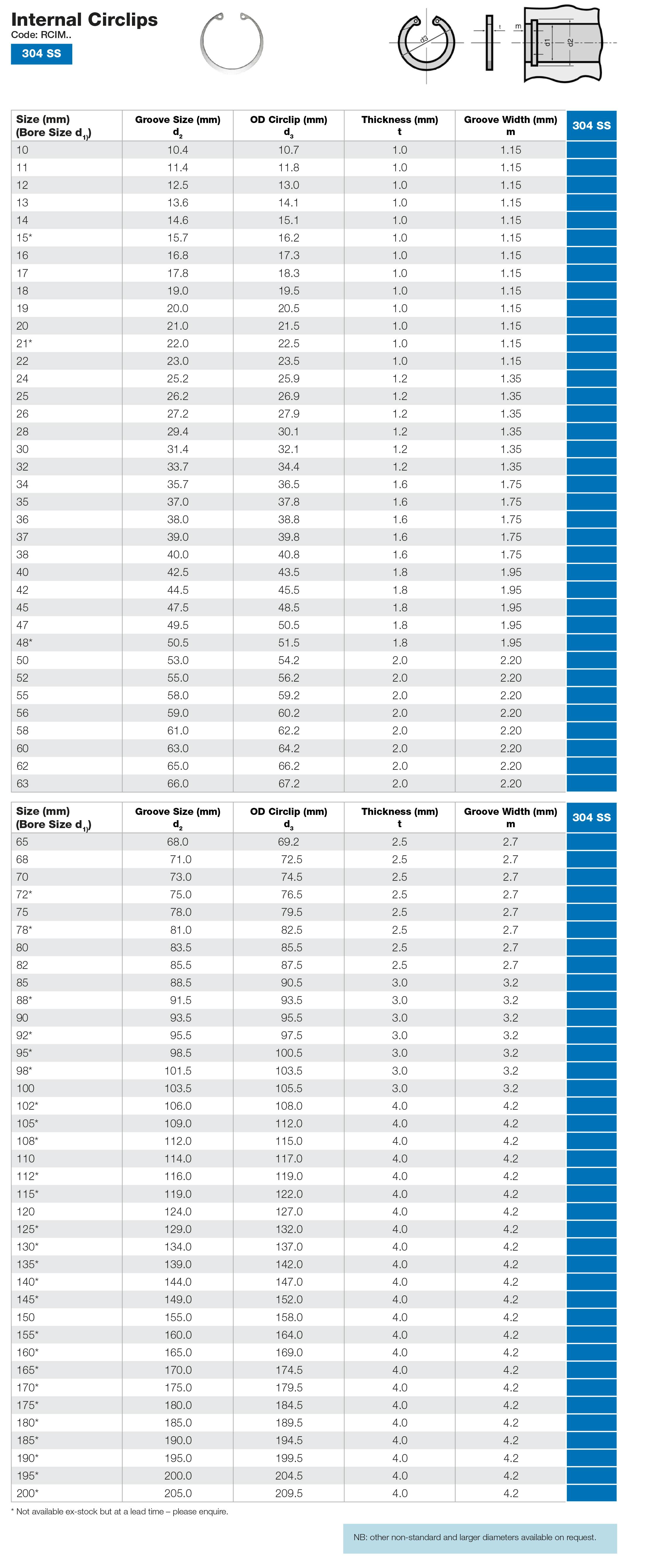

Internal Circlip Sizes Pdf

E Clip Size Chart

E Type Circlips Diameter M3M100 Millimeter (Mm) at Best Price in New

circlip std.pdf

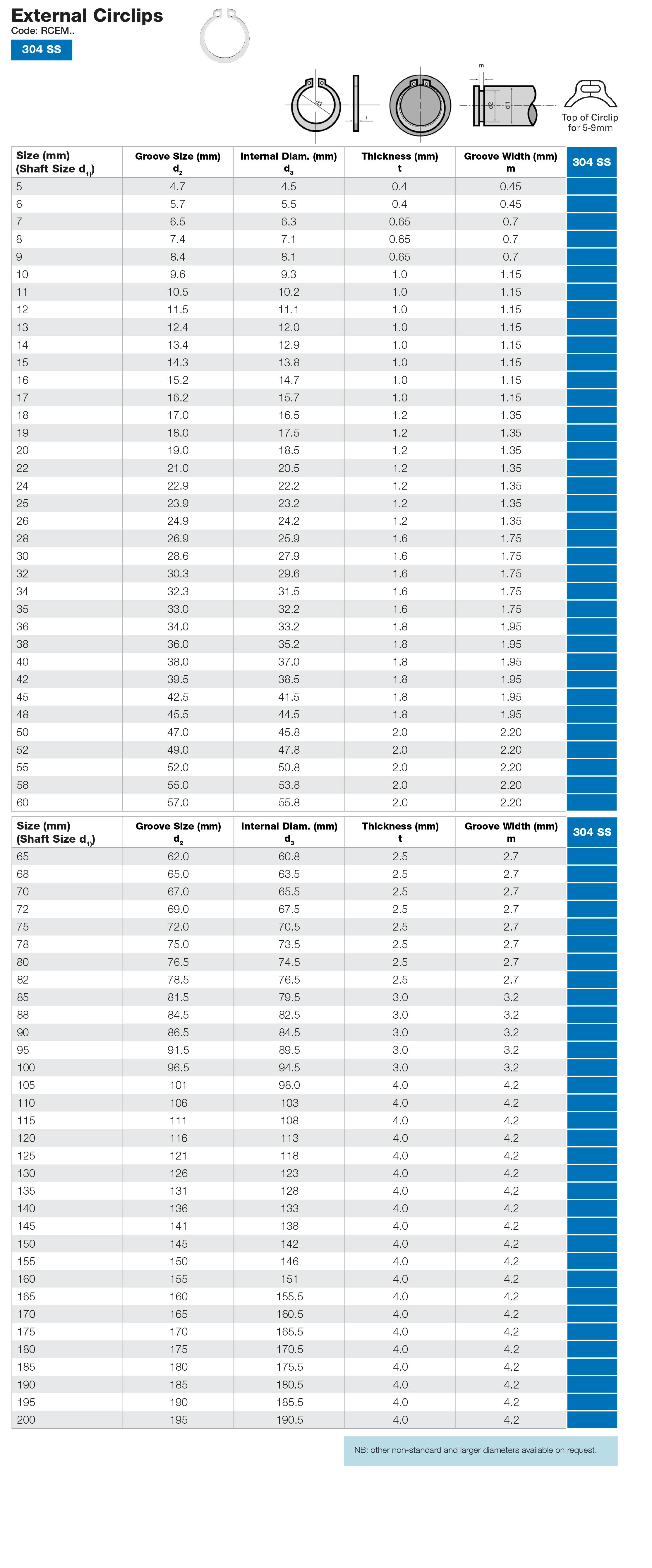

External Circlip Dimensions Anzor

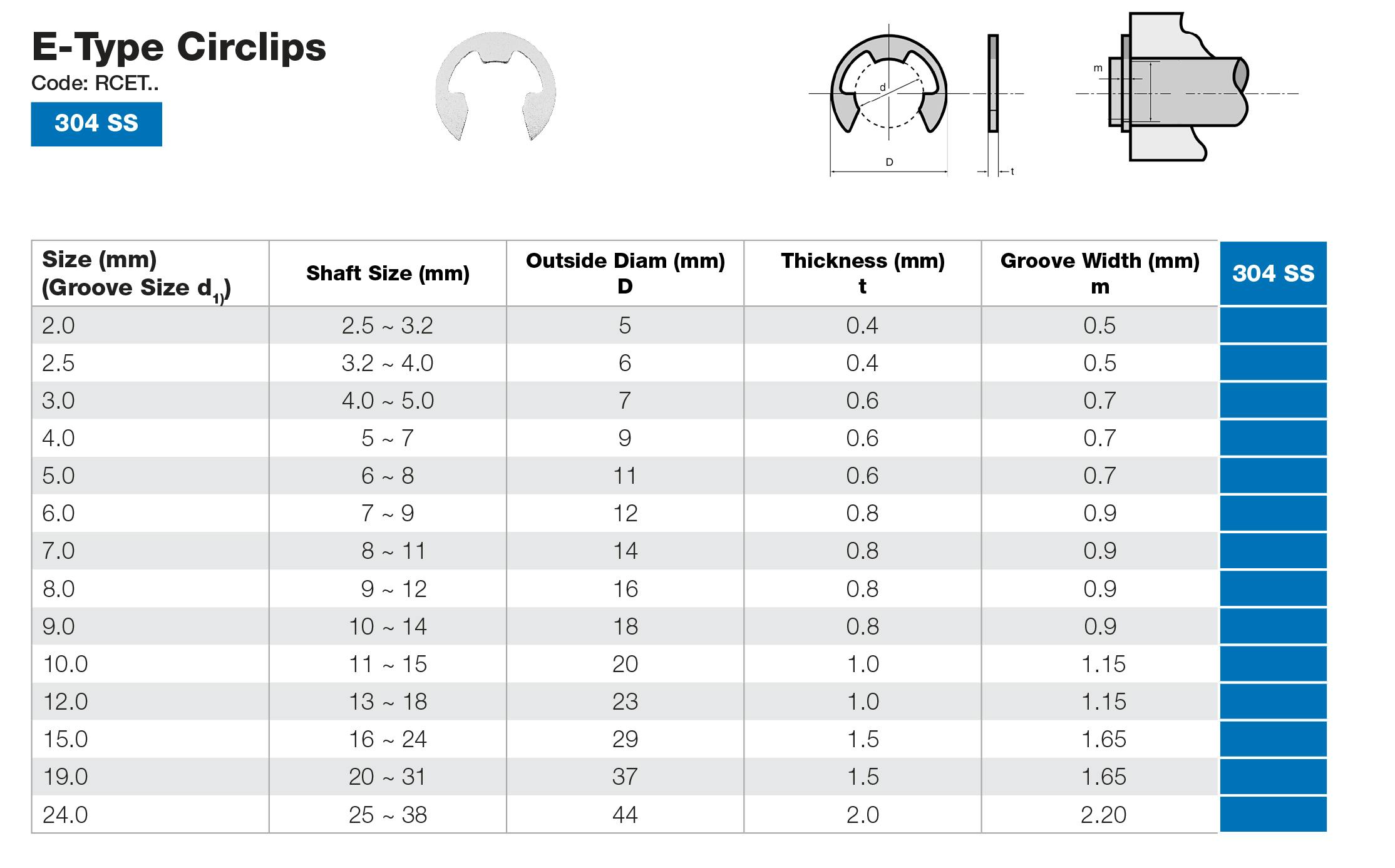

Stainless E Type Circlip Dimensions Anzor

E Type Circlip Dimensions

Circlip Size Chart Pdf

External Circlip Size Chart Metric

Internal Circlip Size Chart Pdf

Finish The Installation By Installing Them Over The Shaft Groove.

(Also Available In Stainless Steel)

This Range Can Be Supplied Stacked On.

They Include Only For Sharp Edges Of Stressed Surfaces In.

Related Post: