Cylinder Head Bolt Torque Chart

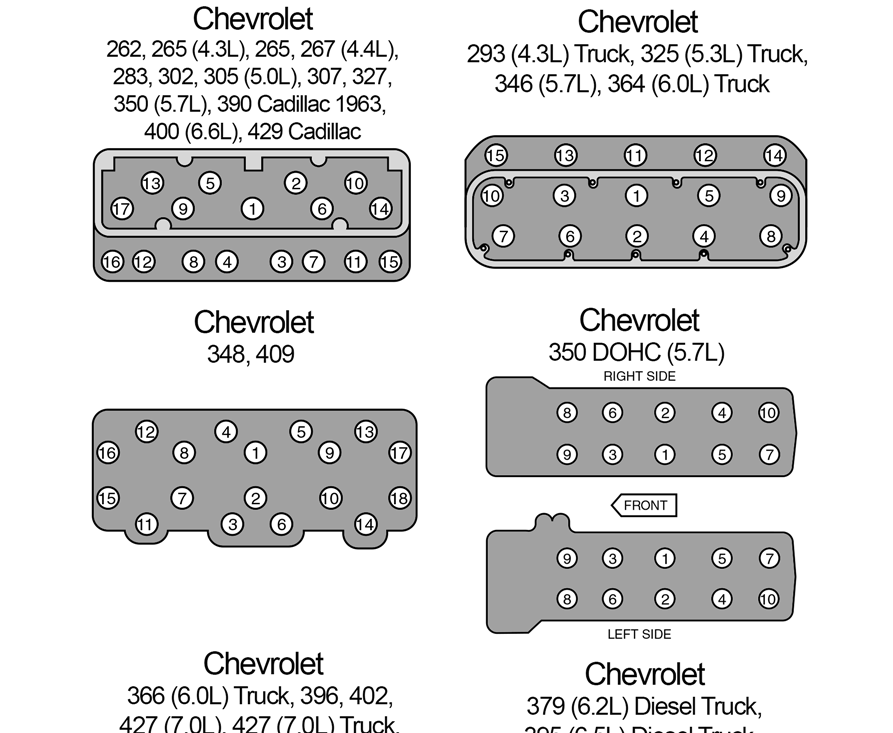

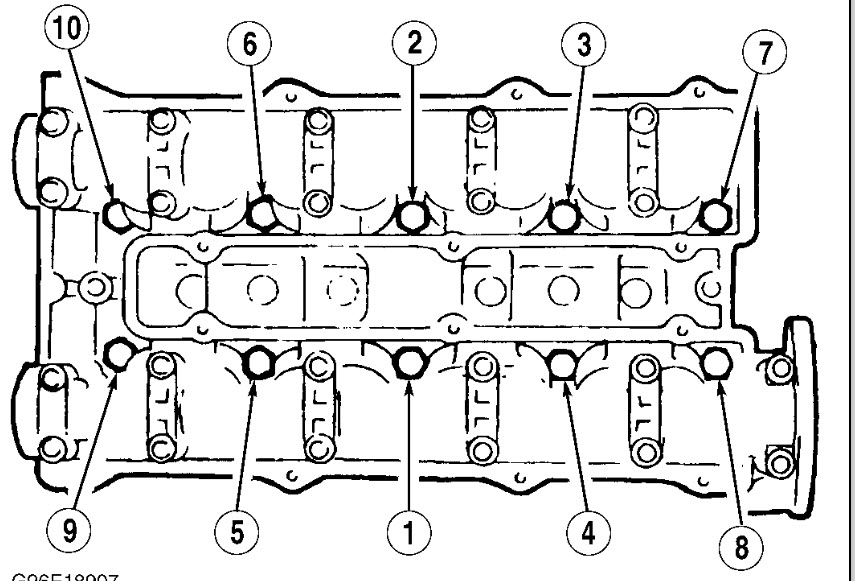

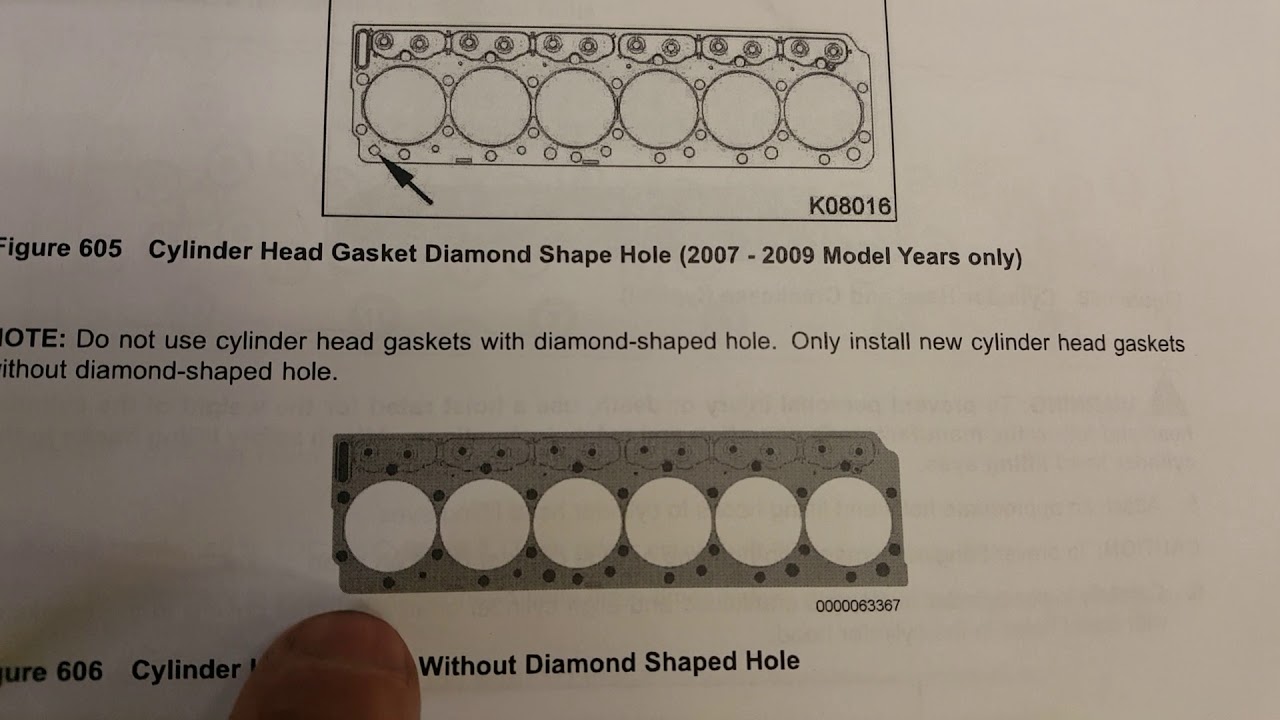

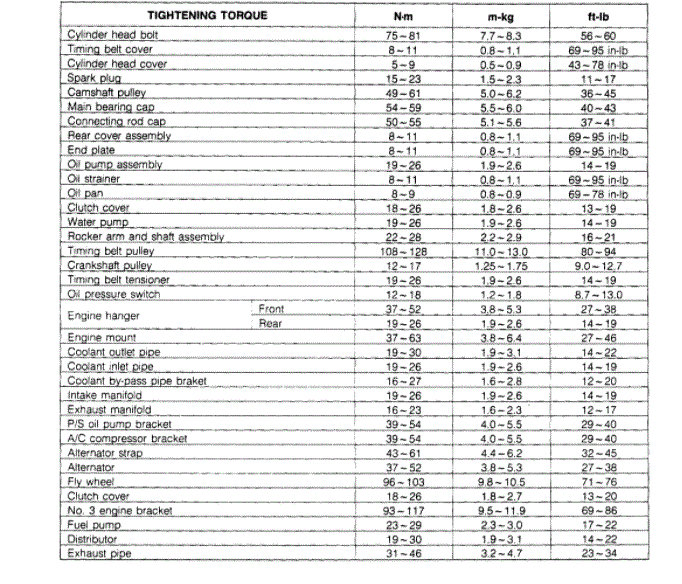

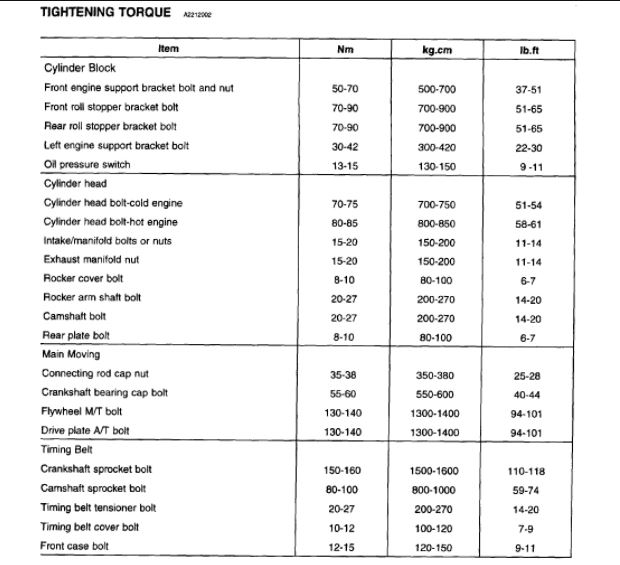

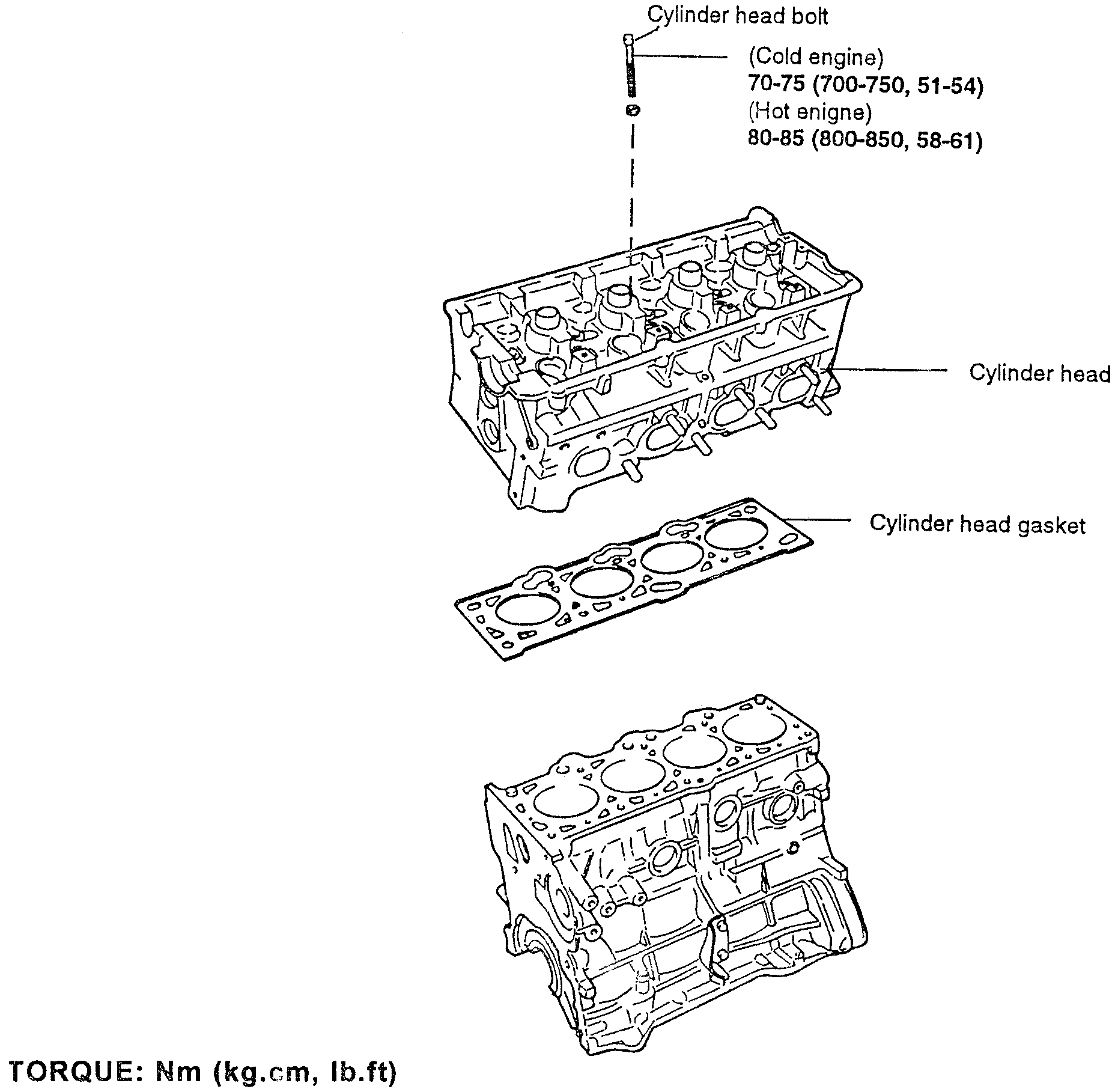

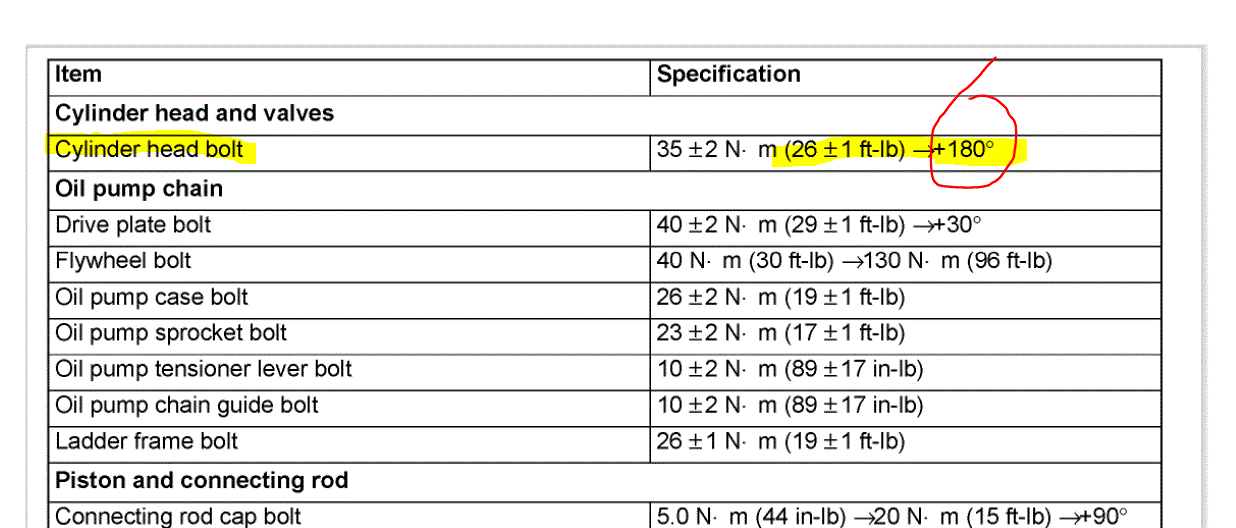

Cylinder Head Bolt Torque Chart - Mark each head bolt and head with aligning marks. Model n, np, and nr: Head bolt torque specs are among the most common, and a few need to know the main bearing torque for things like the briggs & stratton intek 311777. Lbs.) and newton meters (nm) for the cylinder head bolts: Model t, u, and y: To ensure the proper torque of the head bolts on the toyota 4y engine, follow these steps: Web you have the correct torque specs and sequence, now it's just a matter of doing it. Tighten each bolt 1/4 turn (90 degrees). Web to properly torque the head bolts of a cat c15 engine, follow these steps: Web tighten the cylinder head bolts to 44 ft.lbs. Web head bolt torque (ft. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380 0.1640 0.1900 0.2500 0.3125 0.3750 0.4375 0.5000 0.6250 0.7500 0.8750 1.0000 1.2500 1.5000. Some people do only 1 or 2 steps to reach the final torque. Web when following the torque sequences below,. Grade identification on table 4 for remaining bolts not specified in this table. Model p, r, and s: This allows time for the studs to stretch and settle completely before the next torque application. To ensure the proper torque of the head bolts on the toyota 4y engine, follow these steps: Web when following the torque sequences below, wait approximately. K = 0.15 k = 0.17 k = 0.20. Be sure to have the 12mm serrated wrench fully seated into the head bolt. Web to properly torque the head bolts of a cat c15 engine, follow these steps: #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990 0.1120 0.1250 0.1380. This allows time for the studs to stretch and settle completely before the next torque application. Tighten bolt 1 through bolt 14 in a numerical sequence to 300 ± 15 n·m (220 ± 11 lb ft). Recommended torque with lubricated bolts. #1 #2 #3 #4 #5 #6 #8 #10 1/4 5/16 3/8 7/16 1/2 5/8 3/4 7/8 0.0730 0.0860 0.0990. Begin by tightening all head bolts to 90 ft. Grade identification on table 4 for remaining bolts not specified in this table. The 16v tightening sequence is slightly different than the sequence for the 8v heads. Also, be sure to replace the valve cover gasket with a mb brand. Once they reach this zone, they spring back to provide a. Egr cooler coolant supply port cover (on oil filter base) (m6).89 lbf/in. Model f, fh, and l: Web to properly torque the cylinder head bolts on a 21 hp briggs and stratton engine, it is important to follow the manufacturer’s specifications. Tighten each bolt 1/4 turn (90 degrees). This allows time for the studs to stretch and settle completely before. Start by cleaning the cylinder head and engine block surfaces thoroughly to remove any dirt or debris. Different styles depending on heads and stud diameters. He demonstrates how to find the proper torque sequence for each. Web when following the torque sequences below, wait approximately 15 minutes between torque steps. Mark each head bolt and head with aligning marks. Mark each head bolt and head with aligning marks. For head studs or aftermarket bolts check your instructions, sbc studs are available in a ton of. Some people do only 1 or 2 steps to reach the final torque. Web when following the torque sequences below, wait approximately 15 minutes between torque steps. Once all bolts are initially torqued, repeat. Again, tighten bolt 1 through bolt 14 in a numerical sequence to 130 ± 15 n·m (95 ± 11 lb ft). (122 nm) in the numerical order provided in the torque sequence table above. Web head bolt torque (ft. Different styles depending on heads and stud diameters. Head bolt torque specs are among the most common, and a few need. Different styles depending on heads and stud diameters. Some people do only 1 or 2 steps to reach the final torque. Recommended torque with lubricated bolts. Refer to the 16v cylinder head and head gasket removal and. Egr cooler coolant supply port cover (on oil filter base) (m6).89 lbf/in. For each cylinder head, start with head bolt numbered one. For head studs or aftermarket bolts check your instructions, sbc studs are available in a ton of. Refer to the 16v cylinder head and head gasket removal and. (122 nm) in the numerical order provided in the torque sequence table above. Egr cooler coolant supply port cover (on oil filter base) (m6).89 lbf/in. Web from there, you can determine the cylinder head torque specifications right down to the valve clearance for intake and exhaust if needed. Lbs.) head bolt torque (nm) model a, b, and z: Web small block chevy head bolt torque specifications. He demonstrates how to find the proper torque sequence for each. These bolts are engineered to stretch within a controlled “yield zone”. Tighten each bolt 1/4 turn (90 degrees). Begin by tightening all head bolts to 90 ft. Model p, r, and s: Some people do only 1 or 2 steps to reach the final torque. Web here are the head bolt torque specifications for the toyota 4y engine: Tighten bolt 1 through bolt 14 in a numerical sequence to 130 ± 15 n·m (95 ± 11 lb ft).

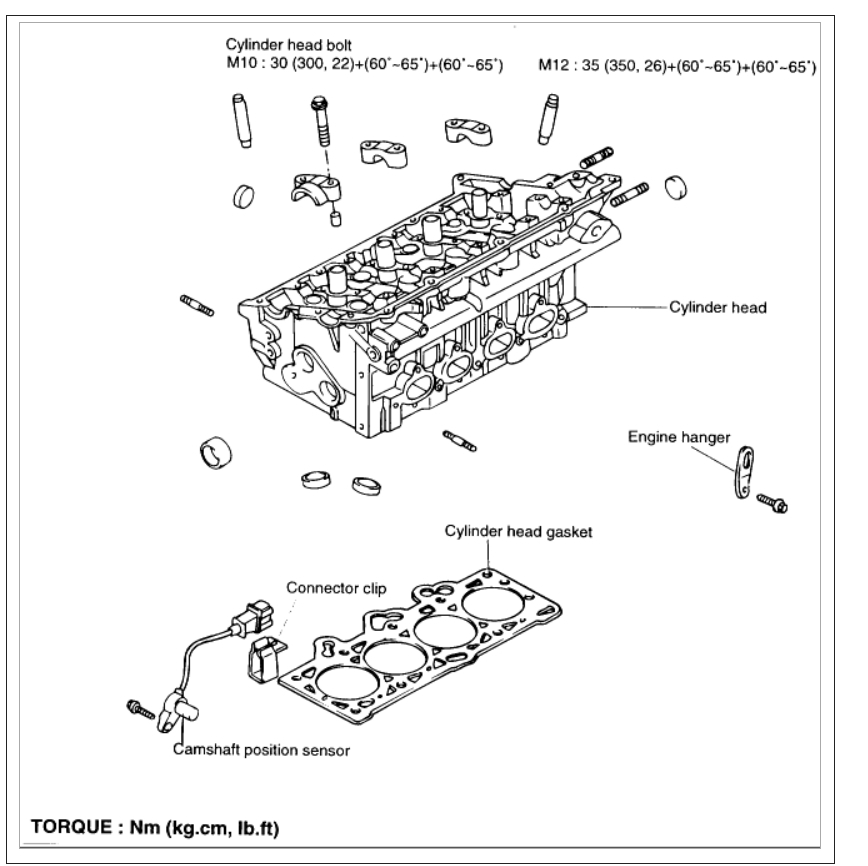

Repair Guides Engine Mechanical Cylinder Head

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Chart

MaxxForce DT Cylinder Head Torque Specs YouTube

Torque Setting for Cylinder Head Specs I Need to Know Torque

Cylinder Head Bolt Torque Chart

NEED CYLINDER HEAD TORQUE SPECS AND TIGHTENING SEQUENCE FOR 4CYL A12

Cylinder Head Bolt Torque Chart

Cylinder Head Bolt Torque Chart

Are You Going To Check The Length Of The Head Bolts To Make Sure They Are All The Correct?

Web When Following The Torque Sequences Below, Wait Approximately 15 Minutes Between Torque Steps.

Different Styles Depending On Heads And Stud Diameters.

Start By Cleaning The Cylinder Head And Engine Block Surfaces Thoroughly To Remove Any Dirt Or Debris.

Related Post: