Countersink Size Chart

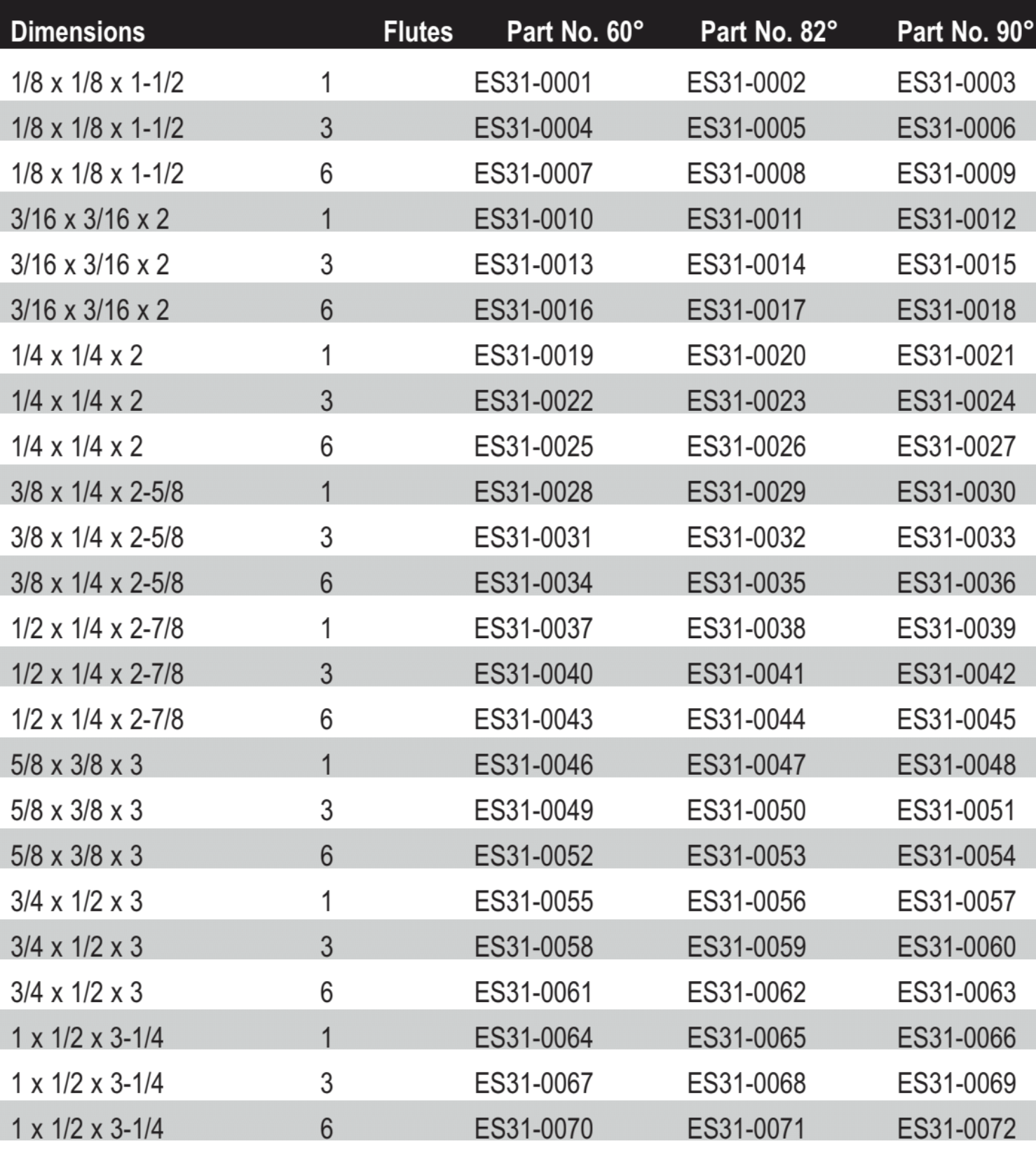

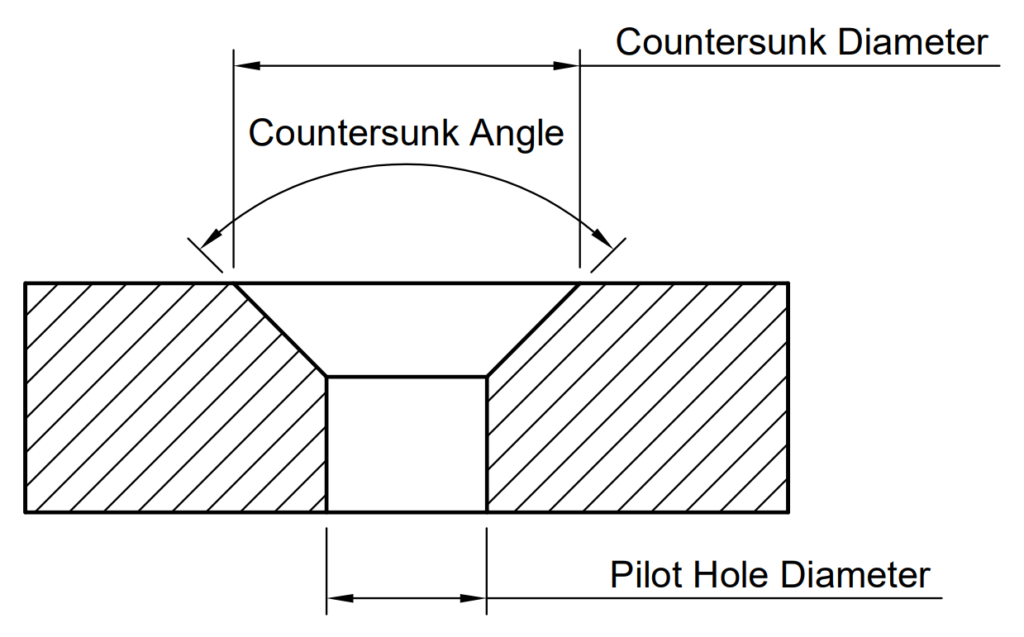

Countersink Size Chart - Web want the head of each screw to sit flush with your wood surface? Web a countersink is an angled taper applied to a hole that allows a fastener (usually a flat head screw or similar) to sit even with, or below the surface which has been countersunk. Countersink depth is typically measured from the surface of the material to the bottom of the countersink hole. How to use a countersink bit. Web this chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units (millimeters). Web what is the difference? The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. When a conical shape element is detected, it will be identified as a countersink. Web use this chart to find out what size countersunk hole to use for ansi socket flat head fasteners. Web countersunk hole size chart for socket flat head fasteners (ansi inch) using the above table, given #6 fastener with a loose fit, we have: Web diameter and depth:the diameter of the countersink hole is determined by the size of the fastener head, ensuring a proper fit and allowing the head to sit flush or below the material surface. A screw placed in a countersunk hole is located by the angle. Modeling rules for countersunk holes. Web this chart shows the dimensions of counterbore and. This is for iso screws and bolts. Web sheet metal countersink chart. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best option depends on your project and part geometry. First, you must select the screw size you're working with (see the left side of the chart). Is a countersink bit for. Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Web to determine the appropriate size countersink drill bit, you can refer to a drill bit sizing chart or consult a tool specialist. Web this chart shows the dimensions of counterbore and countersink holes for different screw sizes, in metric units. In the charts that follow, the theoretical sharp diameter represents the diameter of countersink that will place maximum material condition screwhead flush to the surface of a flat part. Web countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be. This is for ansi inch countersinks. Web countersink hole size charts. These resources will provide you with information on the recommended drill bit sizes for different screw or. The countersunk hole is recognized through two steps below. This is for iso screws and bolts. Web countersunk hole size chart for socket flat head fasteners (ansi inch) using the above table, given #6 fastener with a loose fit, we have: Countersunk screws are simply characterized by their flat head, which allows them to sink into objects and materials. This is for iso screws and bolts. The countersink symbol is used to indicate that a countersink. V 11/32 ±0.005 х 82॰ Web use this chart to find out what size countersunk hole to use for ansi socket flat head fasteners. Can you countersink with a regular drill bit? The purpose of a countersink is to allow a fastener, typically a flathead screw, to sit slightly below the surface of the part. Occasionally, a countersink is used. This short post will give you the exact dimensions you need for your countersunk screws. Countersink modeling and selectable sizes. How to use a countersink bit. Web countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or. Web countersink depth is the depth of a countersink hole, which is a conical hole cut into a material to allow the head of a countersunk screw or bolt to be flush with or below the surface of the surrounding material. First, you must select the screw size you're working with (see the left side of the chart). Is a. The countersunk hole is recognized through two steps below. Machined countersinks are created with a drill press and formed countersinks are made with punch press tooling—the best option depends on your project and part geometry. What controls the location of the screw? Choose from a variety of standard countersink options, which can either be formed or machined into sheet part. Web unsure on what size countersunk hole to use for your ansi inch socket flat head fasteners? Web what is the difference? For example, an ansi inch 9/16″ 100 degree machine screw with a normal fit countersunk hole will require a pilot hole diameter of 5/8″, a countersunk diameter of 1 10/69″, and a countersunk angle of. Web want the head of each screw to sit flush with your wood surface? For example, an ansi metric m4 machine screw with a normal fit countersunk hole will require a pilot hole diameter of 4.5 mm, a countersunk diameter of 9.4 mm, and a countersunk angle of 90°. This is for ansi metric countersinks. In the charts that follow, the theoretical sharp diameter represents the diameter of countersink that will place maximum material condition screwhead flush to the surface of a flat part. The countersunk hole is recognized through two steps below. These resources will provide you with information on the recommended drill bit sizes for different screw or. This is for ansi inch countersinks. Understand the types and use of countersink drill bit, countersink vs counterbore hole and check out the countersink size chart for holes/bits. Web use this chart to find out what size countersunk hole to use for ansi 82 degree machine fasteners. Choose from a variety of standard countersink options, which can either be formed or machined into sheet part parts. Web use this chart to find out what size countersunk hole to use for ansi socket flat head fasteners. First, you must select the screw size you're working with (see the left side of the chart). Web use this chart to find out what size countersunk hole to use for iso flat head fasteners.

Standard Countersunk Hole Diameters Home Interior Design

to West Coast Fasteners Pty Ltd West Coast Fasteners Perth

HSM Machining

Countersink Size Chart Metal

Countersunk Hole Size for Machine Screw (ANSI Metric)

Metric Countersink Dimensions Chart

Counterbore and Countersink Dimensions Chart

Countersink Holes Chart for Drilling Wood Screws Drill Bit Size Guide

Countersink 90° d1=10,4mm d2=6mm DamenCNC B.V.

Countersink Size Chart Metal

How To Use A Countersink Bit.

Web This Chart Shows The Dimensions Of Counterbore And Countersink Holes For Different Screw Sizes, In Metric Units (Millimeters).

Web Use The Image And Chart Below To Determine What Dimensions To Use, All Dimensions Are In Millimetres Apart From The Countersink Angle.

Can You Countersink With A Regular Drill Bit?

Related Post: