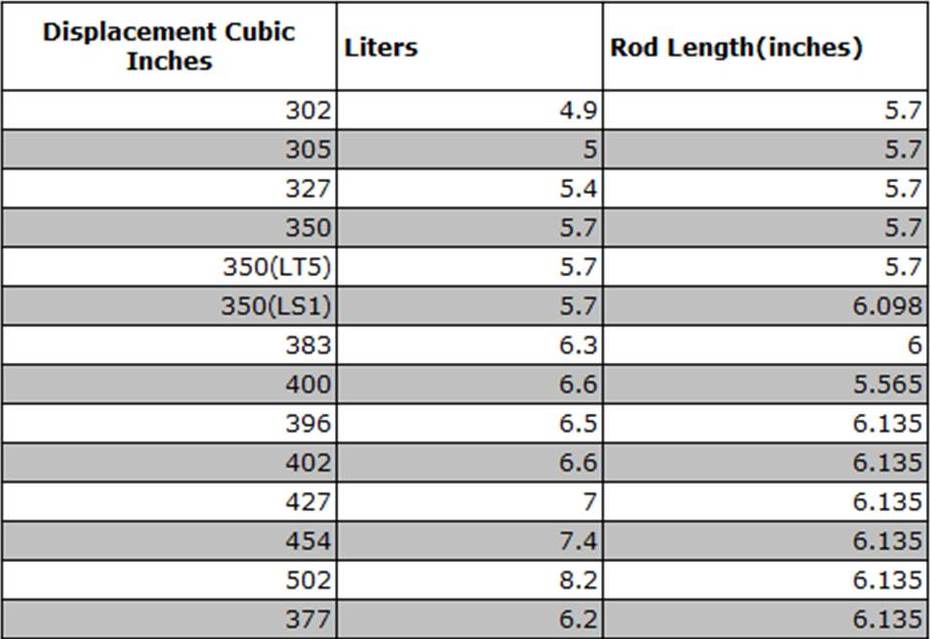

Connecting Rod Length Chart

Connecting Rod Length Chart - The rod ratio in this engine would be 5.7 (rod length) divided by 3.48 (stroke), which equals 1.64. Find the model and year in column 1. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used. Rod ratio is the length of a connecting rod (center to center) divided by the stroke of the crankshaft. Find the motor type in column 1. The most common ratios are in the range of 2.0 to 2.2. To give you an example, let’s look at a standard 4g63, a 2 litre, four cylinder engine. Web what is connecting rod? This number can have a direct effect on power, torque, engine efficiency, and piston wear. Lunati power technical specifications providing connecting rod length information. Web divide rod length by the crank stroke and you get the rod ratio. Connecting rods connect the pistons to the crankshaft in internal combustion engines. Web ever hear the term “rod ratio”? Confirm the stroke length in column 3:. Measured (all are approximate or nominal): The most common ratios are in the range of 2.0 to 2.2. Web the conrod length is measured, as shown below, from the centre of the big end to the centre of the small end. Rod ratio is the length of a connecting rod (center to center) divided by the stroke of the crankshaft. Web if you’re building a stock. Rod center to center length. Find the model and year in column 1. Also, download the pdf file. Web by larry carley. Web rod length and rod ratio. Find the motor type in column 1. Lunati power technical specifications providing connecting rod length information. The crank throw, connecting rod and piston must all fit within the block height dimension so that the piston deck comes nearly flush with the deck surface at tdc. Most late model stock engines use powder metal rods. Web race engineering stocks the following. Find the model and year in column 1. They say an engine is only as reliable as its weakest link. The stroke length is almost always chosen first as it relates to the bore and stroke combination for the desired displacement. Web a connecting rod is measured between the centers of the crankshaft journal bore and the piston pin bore.. Web popular longrod lengths for the small block are 5.850, 6.000, and 6.125, but some companies make rods as long as 6.25 inches. Also, download the pdf file. Web by larry carley. Parts, applications, and types of connecting rod explained with diagram. Connecting rods connect the pistons to the crankshaft in internal combustion engines. This number can have a direct effect on power, torque, engine efficiency, and piston wear. Measure the inner diameter of the connecting rod's smaller hole using the caliper's inner jaws. Confirm the stroke length in column 3:. Web what is connecting rod? Most late model stock engines use powder metal rods. The connecting rods that join the pistons with the crank can be a strong link or a weak link depending on the rods that are used. The stroke length is almost always chosen first as it relates to the bore and stroke combination for the desired displacement. Web divide rod length by the crank stroke and you get the rod. Also, changing the rod length will require new pistons with the correct compression height. The most common ratios are in the range of 2.0 to 2.2. Web a connecting rod is measured between the centers of the crankshaft journal bore and the piston pin bore. Rod length is usually specified next, based on the application. Measured (all are approximate or. Find the motor family table: Across the female rod big end. Parts, applications, and types of connecting rod explained with diagram. Also, download the pdf file. Confirm the stroke length in column 3:. They say an engine is only as reliable as its weakest link. Web ever hear the term “rod ratio”? Connecting rods connect the pistons to the crankshaft in internal combustion engines. Also, changing the rod length will require new pistons with the correct compression height. That length is then divided by the stroke of the crankshaft. Web connecting rod ratio is the mathematical relationship between the overall length of the connecting rods and the stroke of the crankshaft. Rod ratio is the length of a connecting rod (center to center) divided by the stroke of the crankshaft. Web by larry carley. Measure the inner diameter of the connecting rod's smaller hole using the caliper's inner jaws. It can be listed in inches or millimeters. But if you are building a 383 stroker with 6.000˝ rods, the rod ratio is 1.6 due to the longer stroke of 3.750˝. The connecting rod’s length will impact rod ratio. Divide the number in half. Web a connecting rod is measured between the centers of the crankshaft journal bore and the piston pin bore. Web divide rod length by the crank stroke and you get the rod ratio. Web rod length and rod ratio.

Rod School How to Choose the Right Connecting Rods OnAllCylinders

connecting rod drawing with dimensions differentwaystolacevans

Manley Small Block Chevy Connecting Rods SBC Rods H Beam Rods

Connecting Rod Bearing Sizes

Connecting Rods Callies Precision Engine Components

Connecting rods dimensions for scooters and motorcycles. Krakow parts

Rod School How to Choose the Right Connecting Rods

Repair Guides Specifications Charts Specifications Charts

Geometry and Dimensions of the Connecting Rod Download Scientific Diagram

How to Build Racing Engines Connecting Rods Guide

Web The Conrod Length Is Measured, As Shown Below, From The Centre Of The Big End To The Centre Of The Small End.

Find The Motor Type In Column 1.

Confirm The Stroke Length In Column 3:.

This Is An Important Function In Matching Engine Performance To The Vehicle And Its Specific Racing Requirements.

Related Post: