Carbon Fiber Patterns

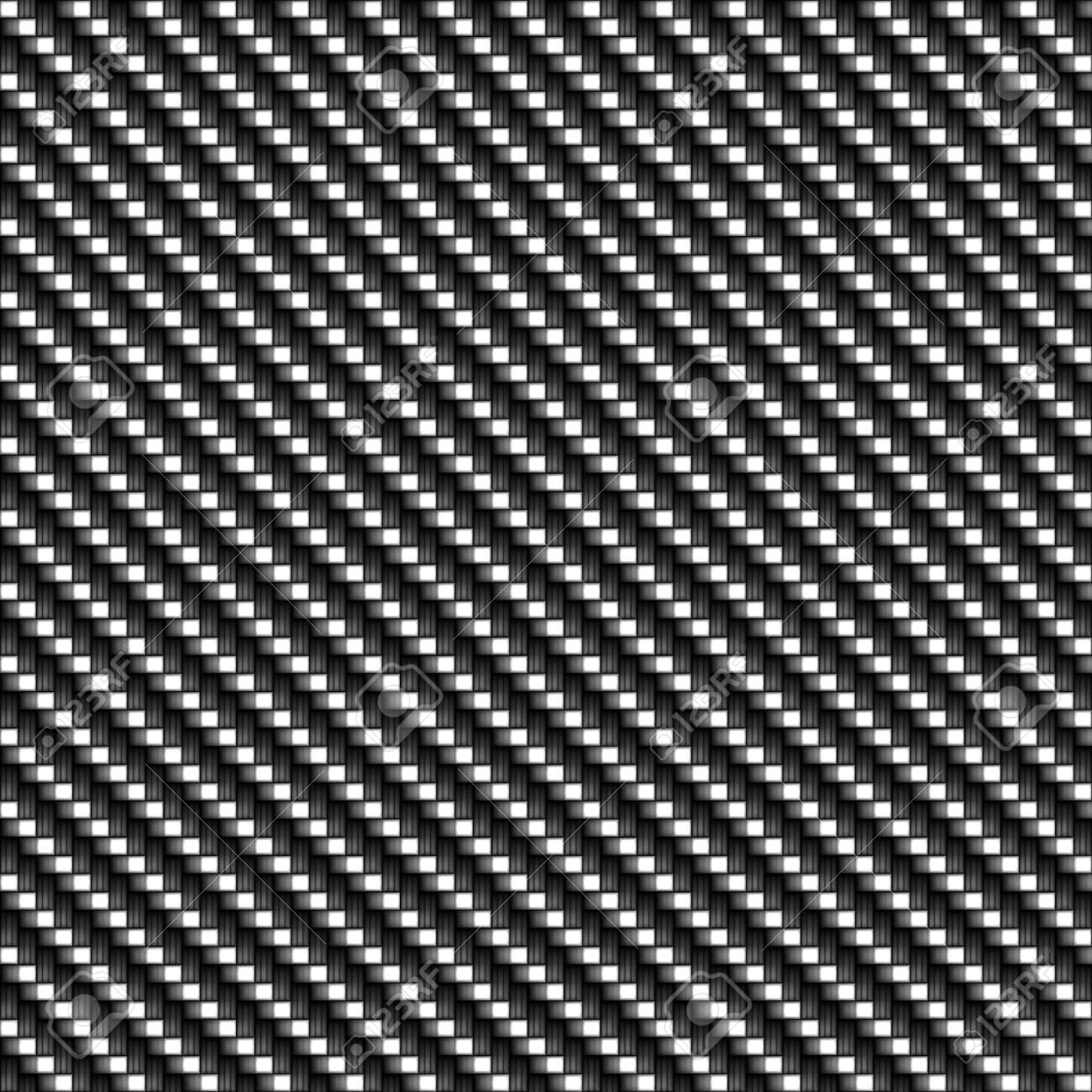

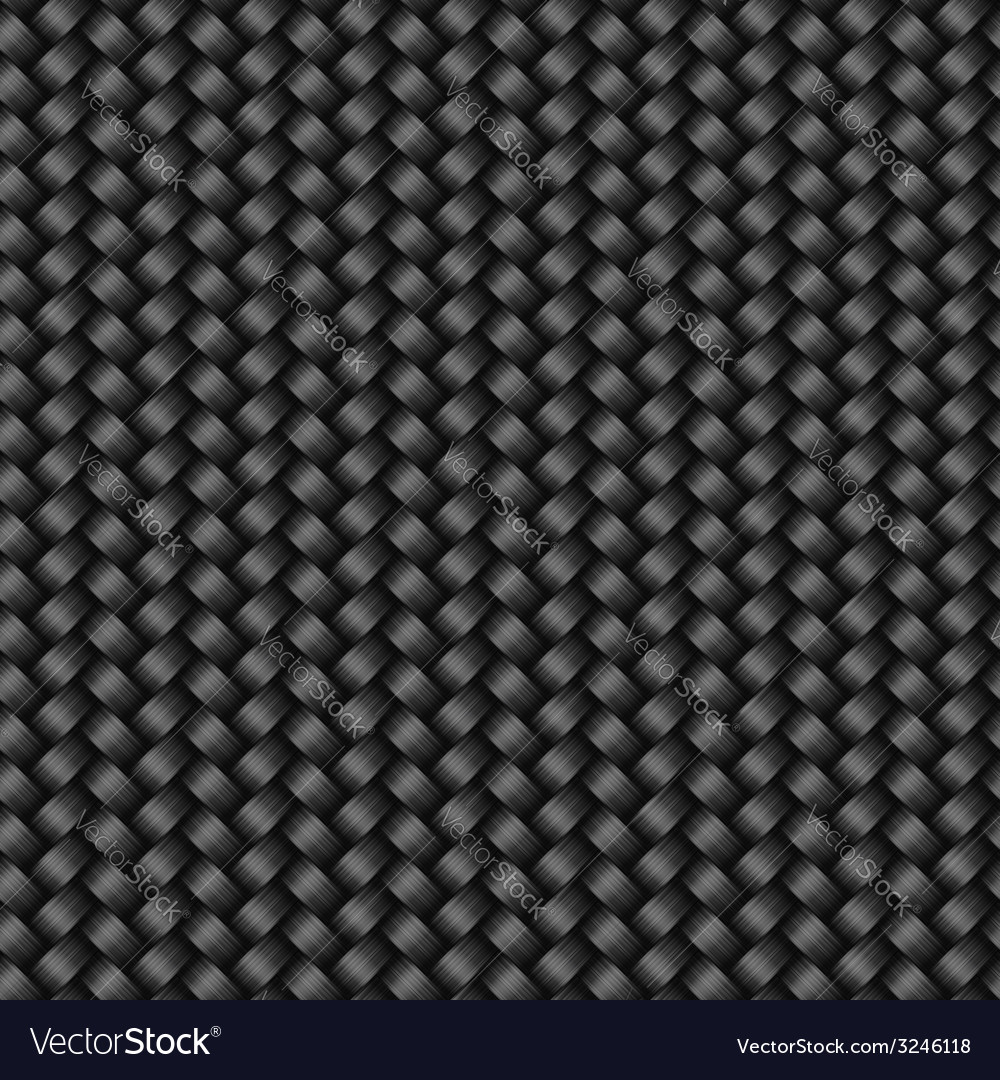

Carbon Fiber Patterns - The weft tows (or fillings) are inserted. When you think about a 2×2 carbon weave look at it as a pattern that goes over two. Web the twill weave is a diagonal pattern that is more commonly used in carbon fiber manufacturing than the plain weave. The 2×2 twill weave is by far the most common carbon fiber fabric used in the automotive industry. 3k is the workhorse of carbon fiber. Web when considering carbon fiber fabric patterns, the harness satin weave stands out as a versatile and effective option for a wide range of demanding applications. Ducati oem carbon is plain weave. Pick the rectangle tool (m) and create a 240 x 100 px shape. Twill weave, on the other hand, is more flexible, making it ideal for more complex shapes and curved surfaces. Carbon fibers have several advantages: However, it’s also much more difficult to drape over a mold than a twill weave. The exposure to extreme heat that follows. Web carbon revolution plc (nasdaq: Web when considering carbon fiber fabric patterns, the harness satin weave stands out as a versatile and effective option for a wide range of demanding applications. 3k carbon fiber is the most popular,. Fill this rectangle with r=67 g=67 b=67 and place it exactly as shown in the first image. This fabric type follows a distinct diagonal pattern. This study aimed to explore how systematic changes in cfp geometrical variations (i.e., thickness and location) can alter plantar pressure. Change the fill color to r=87 g=87 b=87, create a 106 x 100 px shape,. The plate has a classic carbon fiber look. When you think about a 2×2 carbon weave look at it as a pattern that goes over two intersecting warps and under two (hence why it is called 2×2). However, it’s also much more difficult to drape over a mold than a twill weave. Pick the rectangle tool (m) and create a. Carbon fibers have several advantages: Web when considering carbon fiber fabric patterns, the harness satin weave stands out as a versatile and effective option for a wide range of demanding applications. Ducati oem carbon is plain weave. A twill weave has an over/under pattern that creates a diagonal finish. Web the 2×2 twill weave is by far the most common. Ducati oem carbon is plain weave. This weave pattern is known for its distinct. As 3k has a smaller bundle of fibers. When you think about a 2×2 carbon weave look at it as a pattern that goes over two intersecting warps and under two (hence why it is called 2×2). Carbon fibers have several advantages: Because of its high fabric stability, plain. Twill weave, on the other hand, is more flexible, making it ideal for more complex shapes and curved surfaces. Web tenax™ carbon fiber weave patterns. Web this unique style of carbon fiber is simply a twill weave turned 90 degrees. It’s light, relatively stiff, easy to find and simple to use. Web plain weave, or 1x1 weave, carbon fiber fabric is symmetrical and resembles a checkerboard. When you think about a 2×2 carbon weave look at it as a pattern that goes over two. Twill weave, on the other hand, is more flexible, making it ideal for more complex shapes and curved surfaces. As such, it’s a much tighter knit and. Pick the rectangle tool (m) and create a 240 x 100 px shape. Web 5 genuine carbon fiber textures for photoshop. A twill weave has an over/under pattern that creates a diagonal finish. Web raw carbon fiber from tows (or yarns) is woven together to make carbon fiber fabrics (or carbon fiber cloth). To understand the x2 twill weave pattern,. Pick the rectangle tool (m) and create a 240 x 100 px shape. 3k carbon fiber is the most popular, most common carbon fiber. Web this unique style of carbon fiber is simply a twill weave turned 90 degrees. The carbon fiber manufacturing process begins with carbonization. As such, it’s a much tighter knit and much harder to warp. Web the 2×2 twill weave is by far the most common carbon fiber fabric used in the automotive industry. 125 blue carbon fiber check. Pick the rectangle tool (m) and create a 240 x 100 px shape. Twill weave, on the other hand, is more flexible, making it ideal for more complex shapes and curved surfaces. The plate has a. The blanks for our rings are then precision machined out of these carbon fiber sheets using special cnc. This fabric type follows a distinct diagonal pattern. Ducati oem carbon is plain weave. The carbon fiber manufacturing process begins with carbonization. The tows are woven in an over/under pattern, offering tightly interlaced fibers which are highly stable. A twill weave has an over/under pattern that creates a diagonal finish. 5hs = 5 over 1. Twill weave, on the other hand, is more flexible, making it ideal for more complex shapes and curved surfaces. It’s light, relatively stiff, easy to find and simple to use. Web plain weave, or 1x1 weave, carbon fiber fabric is symmetrical and resembles a checkerboard. Fabric stability refers to a material’s ability to maintain its fiber orientation and weave angle. Crev) is the parent of carbon revolution limited, an australian technology company, which has successfully innovated, commercialized and industrialized the advanced. Web the twill weave is a diagonal pattern that is more commonly used in carbon fiber manufacturing than the plain weave. Twill weave carbon fiber is more. Fill this rectangle with r=67 g=67 b=67 and place it exactly as shown in the first image. A satin weave is a method adapted from making silk fabrics, in order.

Carbon fiber seamless patterns Royalty Free Vector Image

Carbon fiber texture seamless 21080

28+ Carbon Fiber Textures, Patterns, Backgrounds Design Trends

28+ Carbon Fiber Textures, Patterns, Backgrounds Design Trends

Black carbon fiber macro texture. Pattern of textile fibres material

Vector Seamless Carbon Fiber Pattern 226409 Vector Art at Vecteezy

30 Free Carbon Fiber Textures Patterns for Designers WebTopic

28+ Carbon Fiber Textures, Patterns, Backgrounds Design Trends

Carbon fiber texture seamless pattern Royalty Free Vector

Carbon Fiber Pattern

Web Carbon Revolution Plc (Nasdaq:

Web This Unique Style Of Carbon Fiber Is Simply A Twill Weave Turned 90 Degrees.

3K Is The Workhorse Of Carbon Fiber.

2×2 Twill Is Likely The Most Recognizable Carbon Fiber Weave In The Industry.

Related Post: