Automotive Wheel Torque Chart

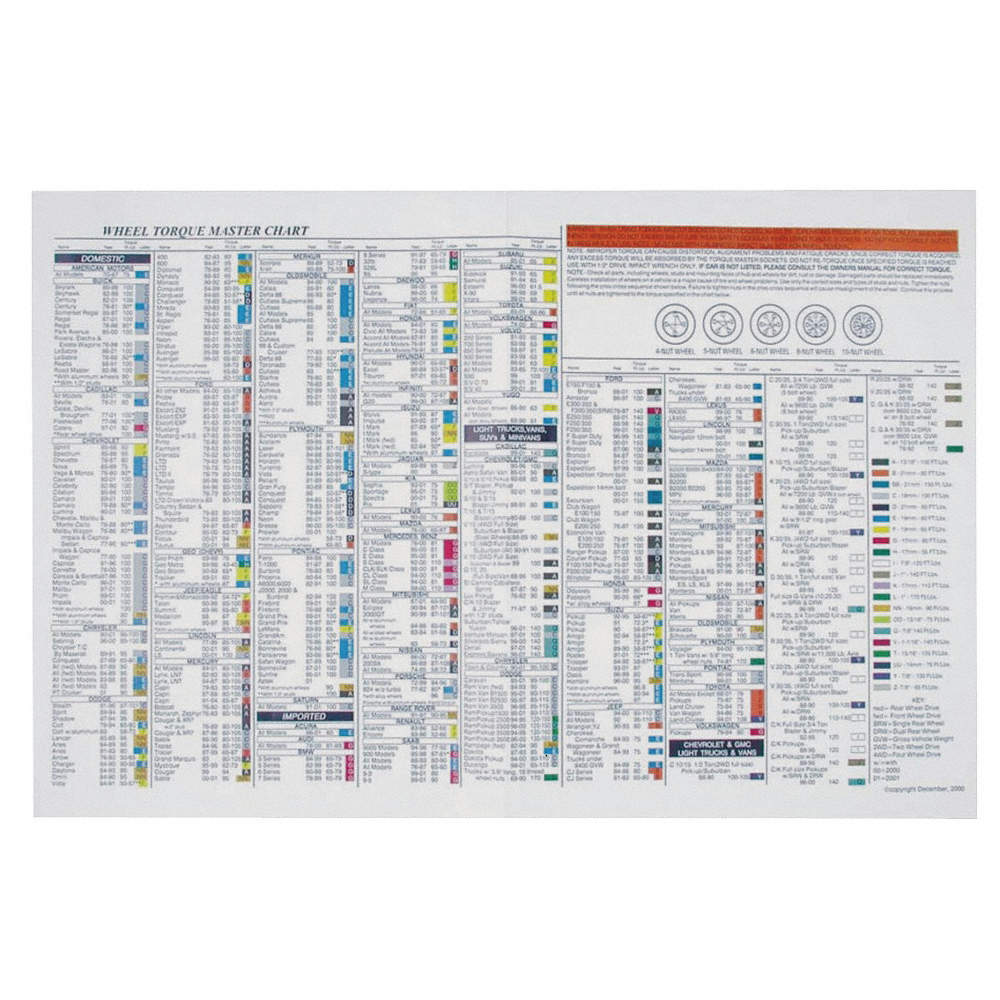

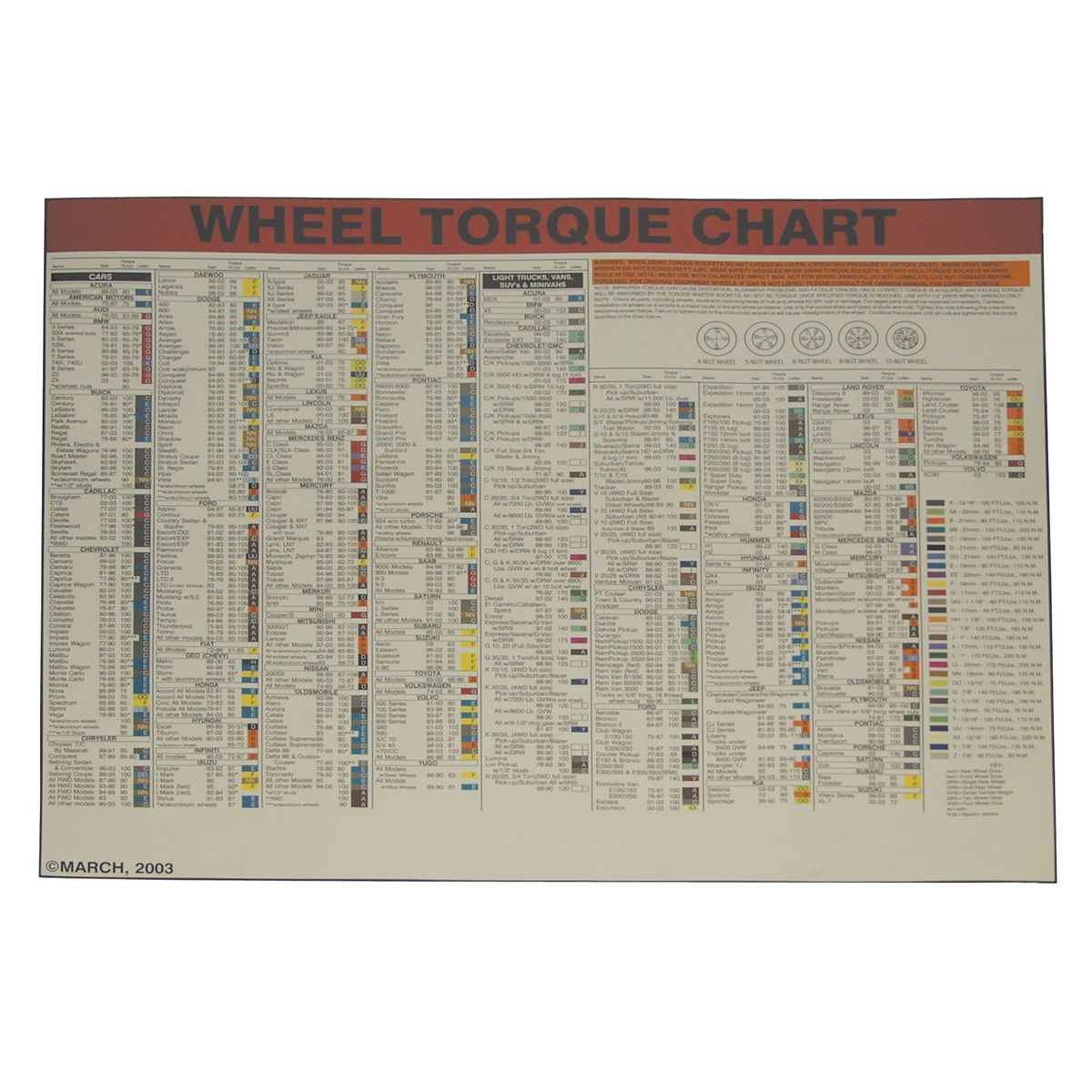

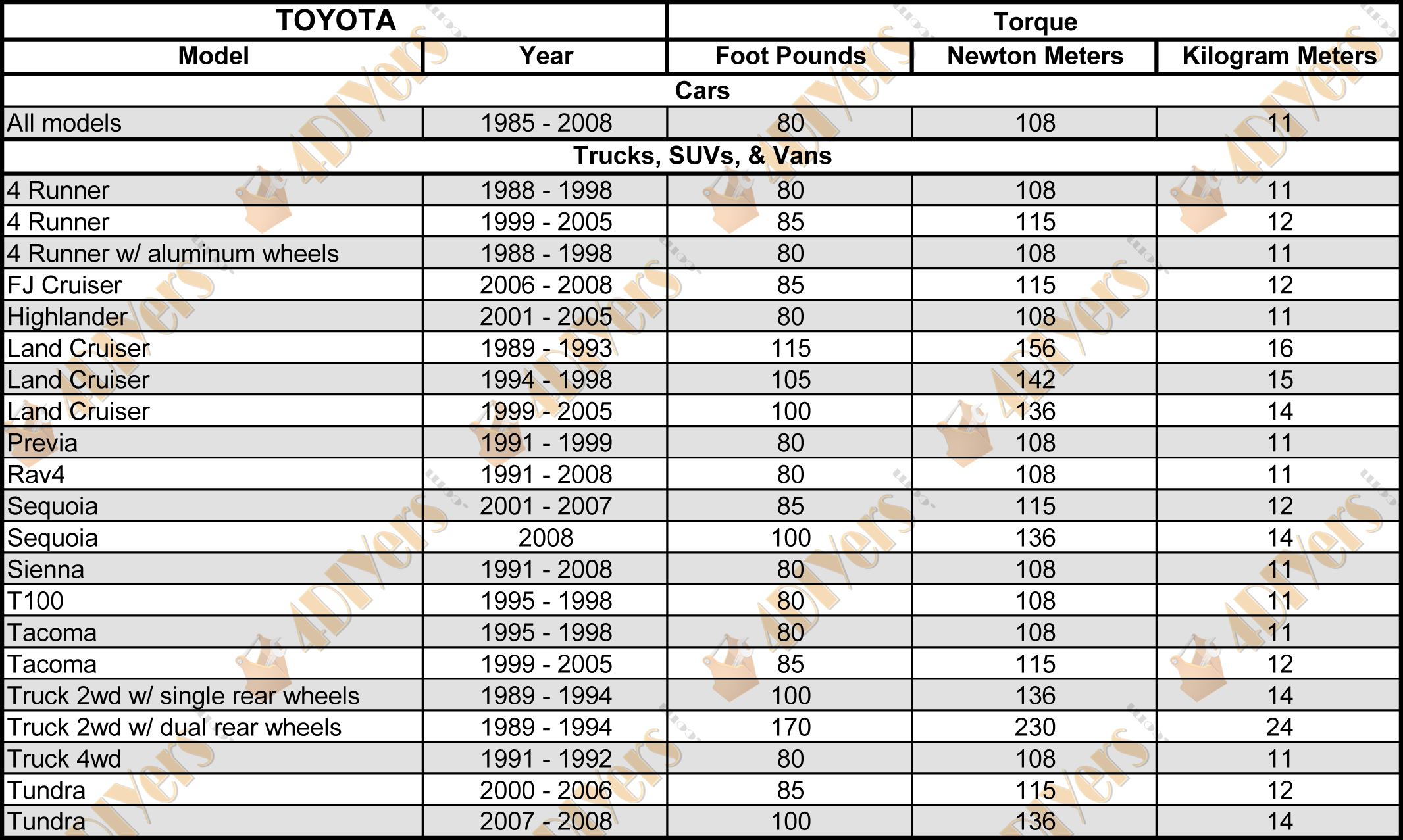

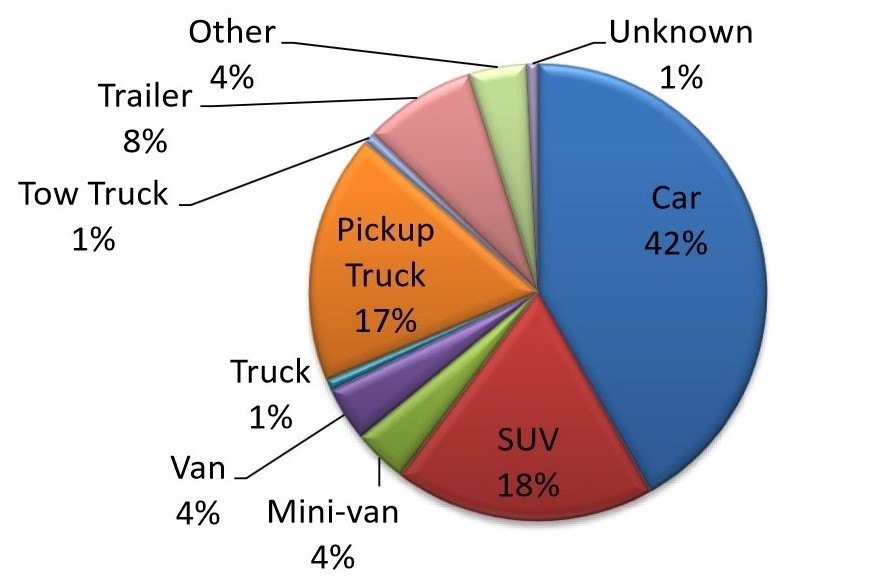

Automotive Wheel Torque Chart - Web it is also important to tighten lug nuts or bolts incrementally to the final torque specification and doing so in the proper sequence. Year range 1990 to 2022. Wall chart provides proper lug nut torque specifications for over 372 cars and light trucks. Proper and accurate torque must be maintained to prevent wheels from loosening, studs from cracking and/or breaking or other possible hazardous breakage resulting in serious injury or death. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. Web referencing a vehicle wheel torque specs chart can help ensure you choose the right product for your specific vehicle. Web once secured hand tight, use the torque wrench set to the proper torque as indicated from a lug nut torque chart or the vehicle’s owner's manual, for the final tightening sequence based on the number of studs or bolts as shown below. Web find the wheel torque specs for your vehicle's lug nuts to properly attach your wheels Potential loss of wheel or broken wheel studs can occur if torque speciication is not correct. Wall chart provides proper lug nut torque specifications for over 372 cars and light trucks. Lbs.) make/model years torque acura all models except: Web torque the lug nuts in two steps, starting at 40 ft/lbs of torque for your first step to get the wheel seated properly. Lug nuts are essential parts of a car’s wheel assembly and they hold. Careless installation of wheels on a vehicle is a major cause of tire and wheel problems. Web wheel nut torque specifications (shown in ft. This chart has the most up to date torque specification for use with original equipment wheels. Understanding and applying the right force is key for secure and safe wheel mounting. Using the proper torque helps ensure. Web with this guide, you can download a free and printable lug nut torque chart pdf to keep in your car. Web using the wrench. Lbs.) make/model years torque acura all models except: Proper and accurate torque must be maintained to prevent wheels from loosening, studs from cracking and/or breaking or other possible hazardous breakage resulting in serious injury or. Year range 1990 to 2022. Web using the wrench. This product is expected to be ship early june 2024. Web wheel nut torque specifications (shown in ft. Click here to purchase the 2022 lug nut torque chart. First up, let’s talk torque units. For a307 grade a, 75% of 36,000 psi is utilized. Web wheel nut torque specifications (shown in ft. Year range 1990 to 2022. Web with this guide, you can download a free and printable lug nut torque chart pdf to keep in your car. Wall chart provides proper lug nut torque specifications for over 372 cars and light trucks. This product is expected to be ship early june 2024. Lug nuts are essential parts of a car’s wheel assembly and they hold the wheel to the car frame. Careless installation of wheels on a vehicle is a major cause of tire and wheel problems.. Web find the wheel torque specs for your vehicle's lug nuts to properly attach your wheels Look for lug nuts that offer a secure fit and compatibility with your car’s specifications for optimal performance and safety. Using a torque wrench involves adjusting the bolt at the bottom of the wrench and then twisting the bottom part of the wrench in. The table can be filtered and is searchable. I’m going to take you through the intricacies of car wheel nut torque specifications. Using the proper torque helps ensure that the wheel assembly is securely installed. Understanding and applying the right force is key for secure and safe wheel mounting. Read on to learn more about the lug nut torque, its. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. All sales are final on this item. Web lug nut torque values cars, light trucks, suvs, and vans * in a star pattern, torque to the first value then repeat & toque to the second value. Lbs.). This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. This product is expected to be ship early june 2024. Web the tire lug nuts should also be properly torqued to secure the wheel to the wheel hub. Web using the wrench. Careless installation of wheels on. Web referencing a vehicle wheel torque specs chart can help ensure you choose the right product for your specific vehicle. Proper and accurate torque must be maintained to prevent wheels from loosening, studs from cracking and/or breaking or other possible hazardous breakage resulting in serious injury or death. This involves using a torque wrench to apply the specified amount of force to each lug nut in a star or crisscross pattern. The graphic below shows the three common bolt patterns and tightening sequences,. Web it is also important to tighten lug nuts or bolts incrementally to the final torque specification and doing so in the proper sequence. It serves as a guide to making sure you apply the right amount of force when installing the lug nuts. Web the tire lug nuts should also be properly torqued to secure the wheel to the wheel hub. Web with this guide, you can download a free and printable lug nut torque chart pdf to keep in your car. Then for the final torque refer to our chart below for torque recommendations based on your lug nut thread size. Durable, folded, coated chart for longer wear. I’m going to take you through the intricacies of car wheel nut torque specifications. Web using the wrench. Web lug nut torque values cars, light trucks, suvs, and vans * in a star pattern, torque to the first value then repeat & toque to the second value. As such, proper torque must be applied to the lug nuts so that the wheel remains secure while you drive. Improper torque can warp the rotor and adversely affect the surrounding components, including the wheel hub. Potential loss of wheel or broken wheel studs can occur if torque speciication is not correct.Printable Automotive Wheel Torque Chart

Printable Automotive Wheel Torque Chart Printable World Holiday

Torque Wall Chart Lock Technology LT1500LWC

Aluminum Wheel Torque Chart

Automotive Wheel Lug Torque Chart Specifications (2022)

Wheel Torque Spec Chart

Printable Automotive Wheel Torque Chart Printable Word Searches

KTool International KTI30103A K Tool Wheel Nut Torque Charts Summit

Wheel Torque Specs Chart

![]()

Suzuki Aerio Torque Specs M8, M6, M10 & G16A JustAnswer

Lbs.) Make/Model Years Torque Acura All Models Except:

Web Now You Are Ready To Use The Proper Torque Sticks.

Web Alright, First Things First.

= Clamp Load For J429 Grade 5 And 8, Fnl Grade 9, A574, Class 4.6, 8.8, 10.9 And 12.9, The Clamp Loads Are Listed At 75% Of The Proof Loads Specified By The Standard.

Related Post: