Aluminium Hardness Chart

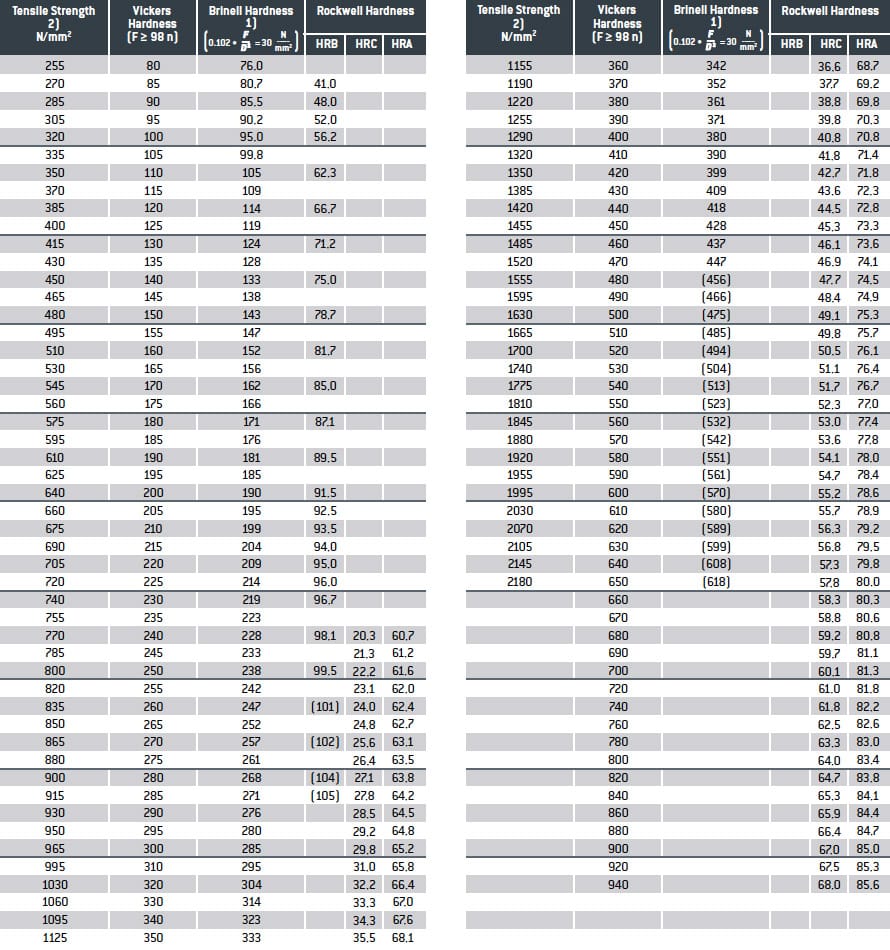

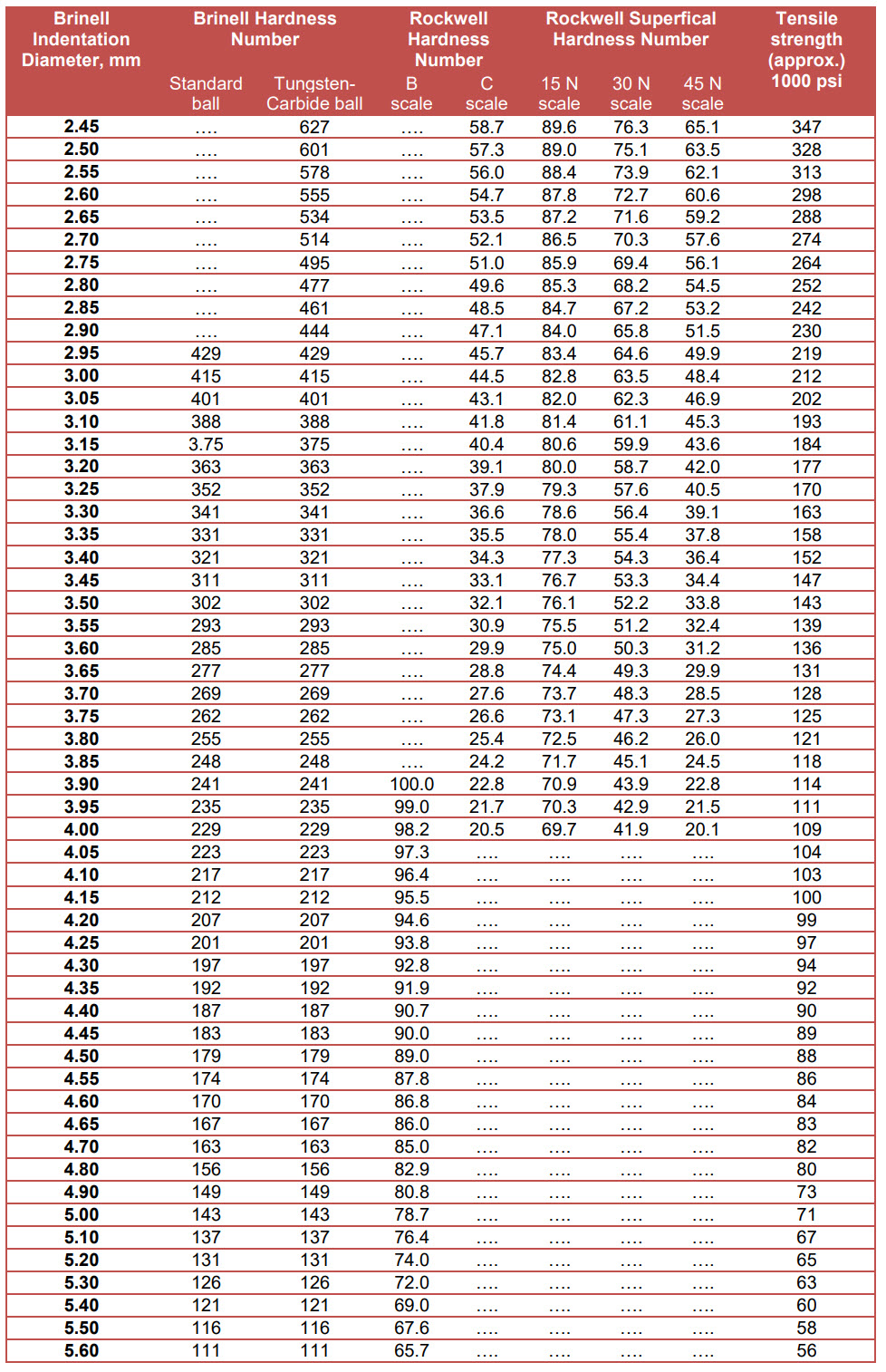

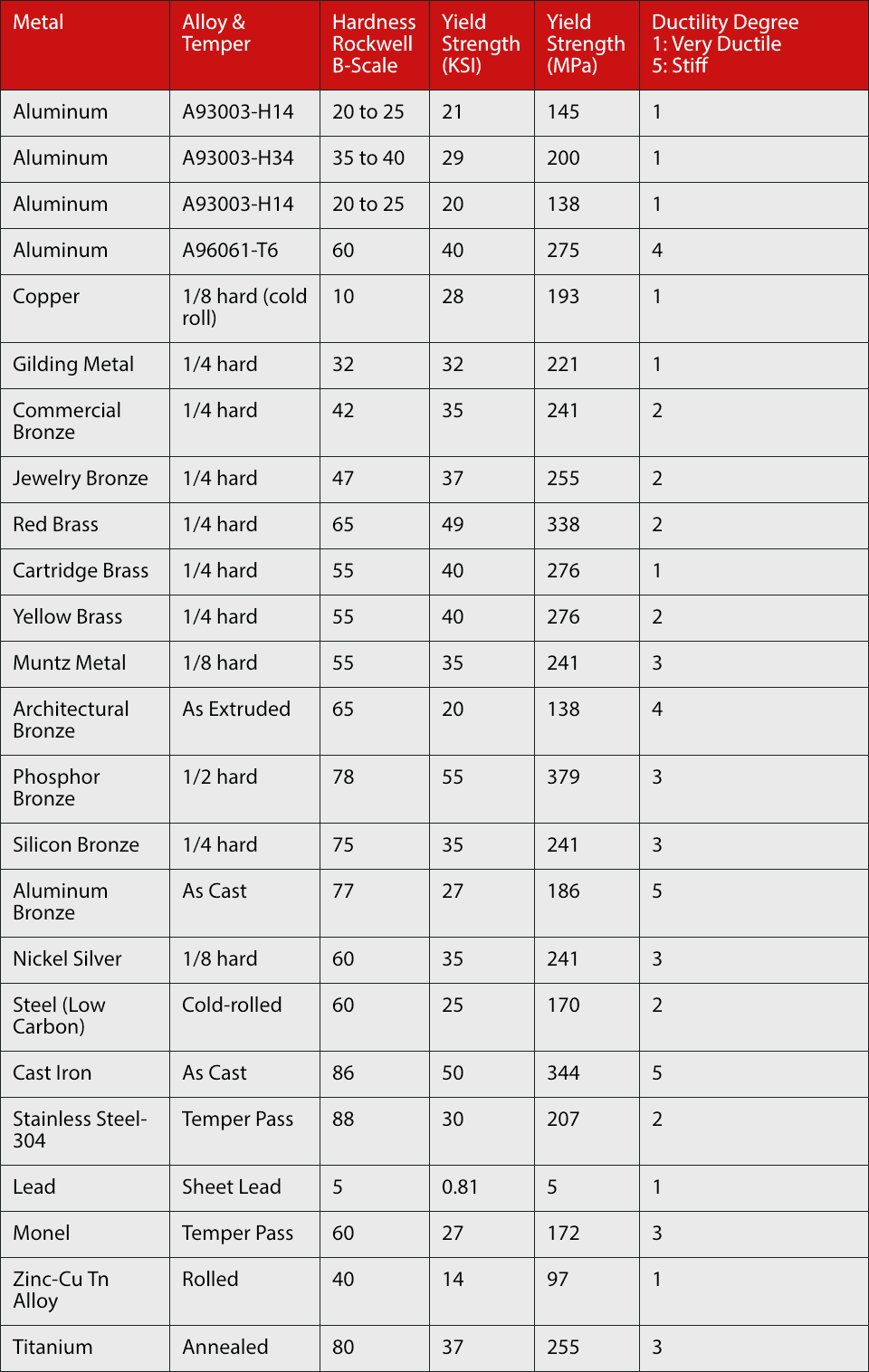

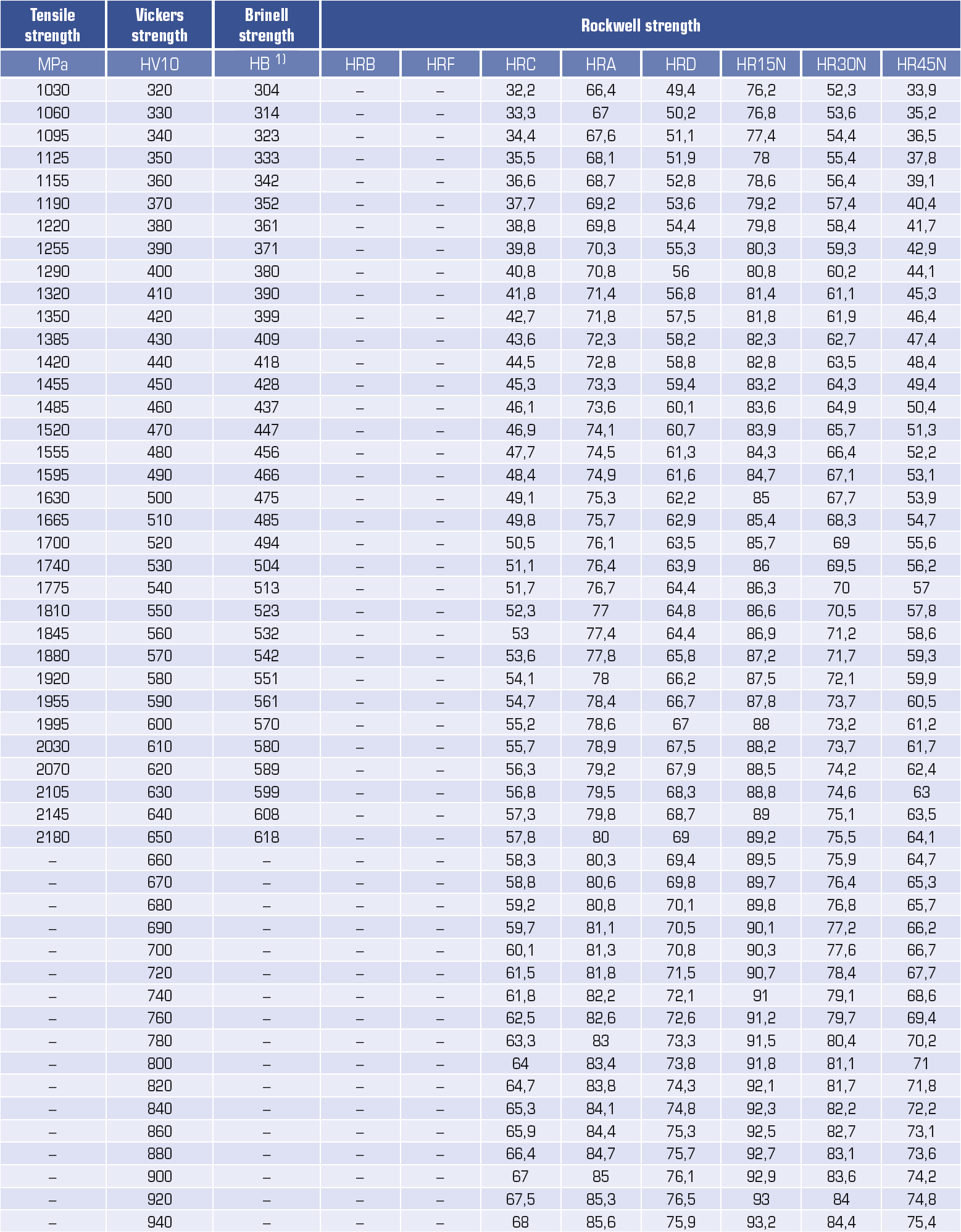

Aluminium Hardness Chart - Web this depends on the size of the slewing ring. Alluminum alloy mechanical engineering properties. Aluminium is most commonly alloyed with copper, zinc, magnesium, silicon, manganese and lithium. Web 1 g/cm3 = 1 kg/dm3 = 1000 kg/m3. Web 73 rows mohs hardness vickers hardness (mpa) brinell hardness (mpa) brinell. Small additions of chromium, titanium,. The ultimate tensile strength is the. Web ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for t6 temper it is about 290 mpa. The following chart give general mechanical engineering properties and data for many common. Find the right alloy with the desired hardness level for your specific application. Web 73 rows mohs hardness vickers hardness (mpa) brinell hardness (mpa) brinell. The rockwell scale is a hardness scale based on indentation hardness of a material. Not only is aluminum alloy a383 (adc12) lightweight but it has a variety of other great properties. Web the ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material,. Aluminium is most commonly alloyed with copper, zinc, magnesium, silicon, manganese and lithium. Brinell hardness of 6061 aluminium alloy depends. Web hardness conversion chart for aluminium. 1 mpa = 1 n/mm2. 1 gpa = 1 kn/mm2. Web explore our expert guide on the common aluminum alloy hardness chart. Web 73 rows mohs hardness vickers hardness (mpa) brinell hardness (mpa) brinell. Web this depends on the size of the slewing ring. The following chart give general mechanical engineering properties and data for many common. The temper designation follows the alloy designation and is separated from it by. Aluminium is most commonly alloyed with copper, zinc, magnesium, silicon, manganese and lithium. Find the right alloy with the desired hardness level for your specific application. The concentration of a contaminant that, if exceeded, triggers treatment or other requirements that a community water system shall follow. Web these conversion tables presents data in the rockwell a, b, c, d, e. Not only is aluminum alloy a383 (adc12) lightweight but it has a variety of other great properties. Beyond alloy selection, temper, which is the hardness and strength imparted to the metal by mechanical or thermal treatment, determines the ultimate. 1 cal/ (g.c) = 1 btu/ (lb⋅f) 6063 aluminum mechanical properties. Brinell hardness of 6061 aluminium alloy depends. Web explore our. The process heats the workpiece to. Brinell hardness of 6061 aluminium alloy depends. 1 cal/ (g.c) = 1 btu/ (lb⋅f) 6063 aluminum mechanical properties. Aluminium is most commonly alloyed with copper, zinc, magnesium, silicon, manganese and lithium. 1 gpa = 1 kn/mm2. Web these conversion tables presents data in the rockwell a, b, c, d, e and f hardness range on the relationship among brinell hardness, vickers hardness, rockwell. Find the right alloy with the desired hardness level for your specific application. 1 cal/ (g.c) = 1 btu/ (lb⋅f) 6063 aluminum mechanical properties. Brinell hardness of 6061 aluminium alloy depends. Beyond alloy. Displays brinell, rockwell b and c, vickers scales equivalents. Alluminum alloy mechanical engineering properties. Find the right alloy with the desired hardness level for your specific application. ( 1 ) taken from nix and gao’s work 26 , using data beyond 500 nm indent depth, such that the. 1 gpa = 1 kn/mm2. The temper designation follows the alloy designation and is separated from it by a hyphen. 1 gpa = 1 kn/mm2. Web this depends on the size of the slewing ring. ( 1 ) taken from nix and gao’s work 26 , using data beyond 500 nm indent depth, such that the. The rockwell scale is a hardness scale based on. The ultimate tensile strength is the. Web a vicker's hardness tester with a 5 kg load was used to measure the hardness of both aluminum and composites, as specified by astm standard e384:08. Find the right alloy with the desired hardness level for your specific application. Beyond alloy selection, temper, which is the hardness and strength imparted to the metal. It has a modulus 8% higher and a. The ultimate tensile strength is the. Web brinell hardness of 2024 aluminium alloy depends greatly on the temper of the material, but it is approximately 110 mpa. Web hardness conversion chart for aluminium. Small additions of chromium, titanium,. Web this depends on the size of the slewing ring. The rockwell test measures the depth of penetration of an indenter under a. Web ultimate tensile strength of 6061 aluminium alloy depends greatly on the temper of the material, but for t6 temper it is about 290 mpa. Web the observed hardness with indentation depth was fitted with eq. Web 73 rows mohs hardness vickers hardness (mpa) brinell hardness (mpa) brinell. Aluminium is most commonly alloyed with copper, zinc, magnesium, silicon, manganese and lithium. The rockwell scale is a hardness scale based on indentation hardness of a material. Not only is aluminum alloy a383 (adc12) lightweight but it has a variety of other great properties. Brinell hardness of 6061 aluminium alloy depends. Web these conversion tables presents data in the rockwell a, b, c, d, e and f hardness range on the relationship among brinell hardness, vickers hardness, rockwell. Web a vicker's hardness tester with a 5 kg load was used to measure the hardness of both aluminum and composites, as specified by astm standard e384:08.

Technical Information Hardness Conversion Table SFC KOENIG

Hardness comparison table according to ISO 18265 Bossard Taiwan

Aluminum Aluminum Hardness

Hardness To Tensile Strength Conversion Conversion Chart and Table Online

Hardness Equivalent Chart

Hardness comparison table WS STAHL

Aluminum Alloy Hardness Chart

Hardness Conversion Chart Pdf

Aluminum Temper Hardness Chart

Aluminum Yield Strength Of Aluminum

The Temper Designation Follows The Alloy Designation And Is Separated From It By A Hyphen.

1 Cal/ (G.c) = 1 Btu/ (Lb⋅F) 6063 Aluminum Mechanical Properties.

Beyond Alloy Selection, Temper, Which Is The Hardness And Strength Imparted To The Metal By Mechanical Or Thermal Treatment, Determines The Ultimate.

Displays Brinell, Rockwell B And C, Vickers Scales Equivalents.

Related Post: