Activated Sludge Troubleshooting Chart

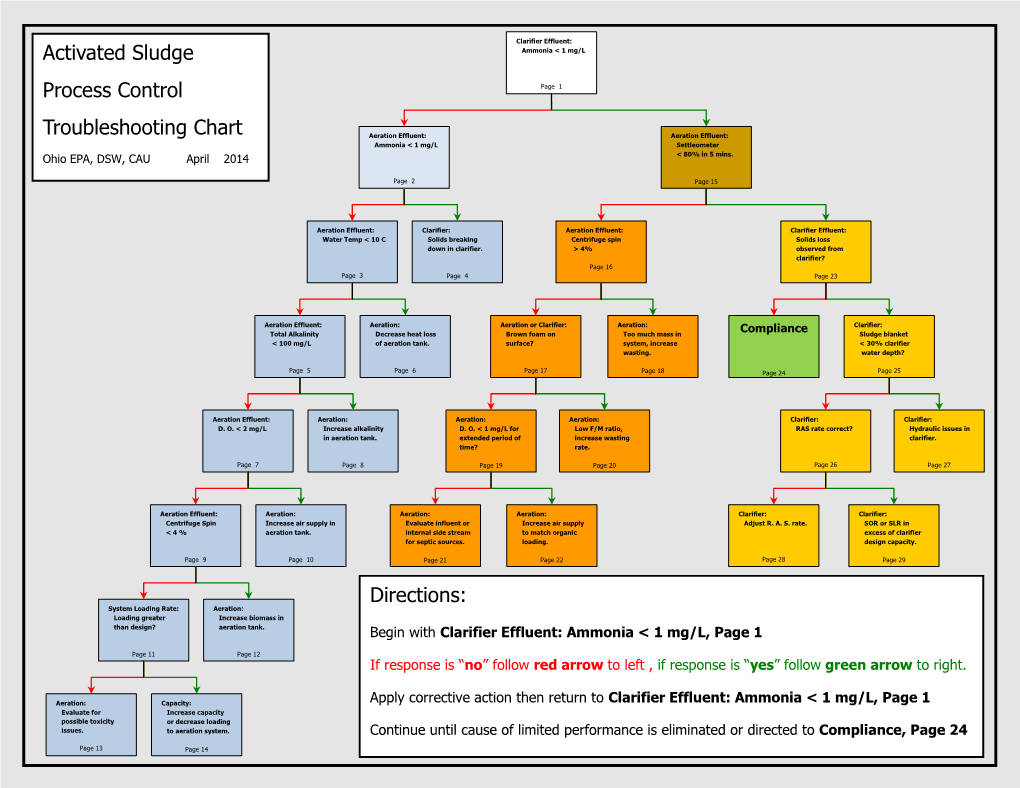

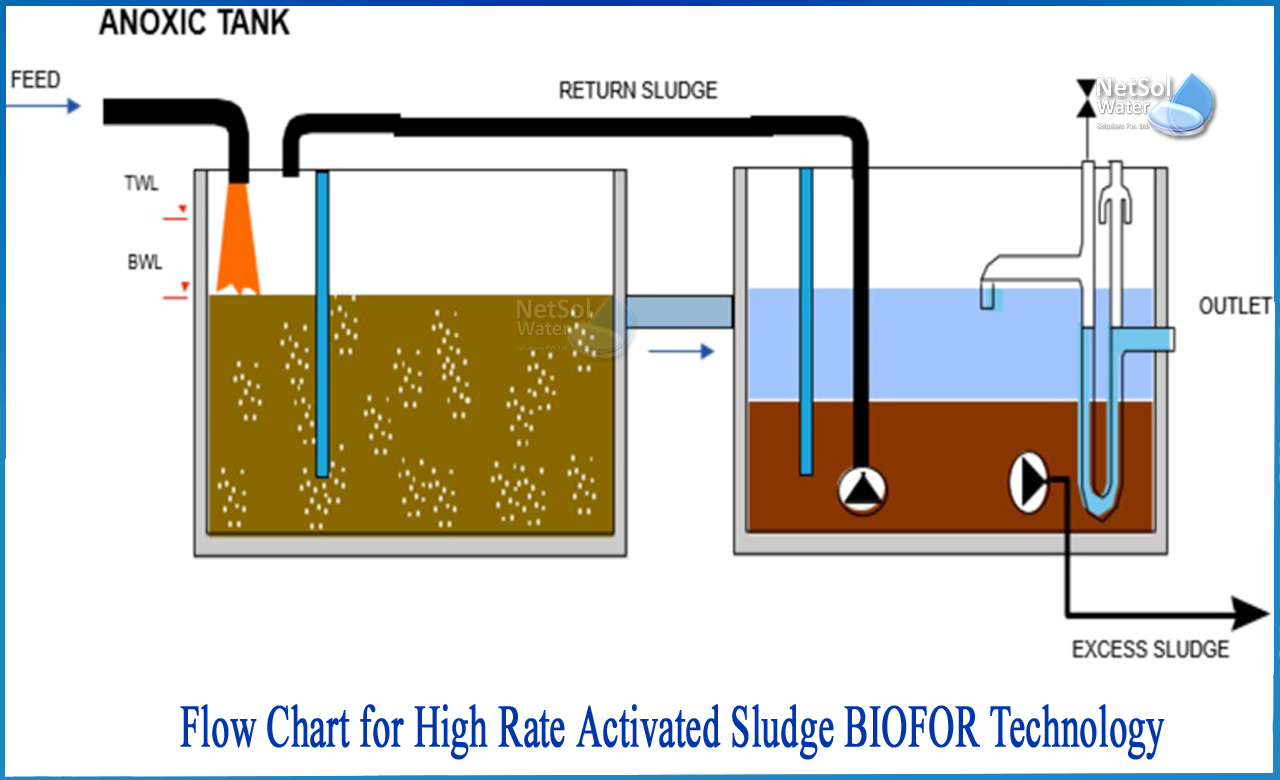

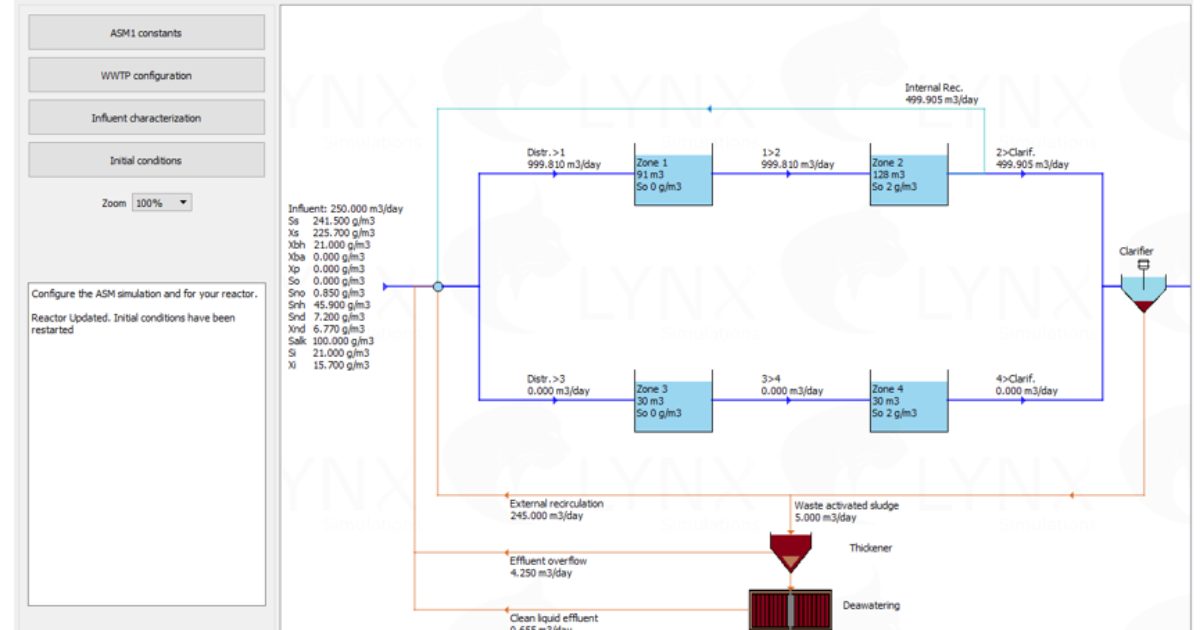

Activated Sludge Troubleshooting Chart - Denitrification is likely if nitrates exceed 10 mg/l. Water temperature impacts growth rate. Check chlorine demand (an increase in. Web the best approach to troubleshooting the activated sludge process is based on microscopic examination and oxygen uptake rate (our) testing to determine the basic cause of the problem or upset and whether it is microbiological in nature. Web begin with box 1: Stated in fundamental terms, the activated sludge process simply involves bringing together wastewater and a mixture of microorganisms under aerobic conditions. Check for nitrates in effluent. Water temperature < 10 c. Measure at effluent water temperature. The object is to aprovide oxygen for organisms or bacteria to grow and reduce the organic waste (bod) in the wastewater. Part ii settleability problems and loss of solids. 1) identify the problem, 2) determine the most likely cause and 3) consider suggested remedies or corrective measures. Identifying and mitigating impacts of drought conditions. Slower growth = slower removal rates. Any of these can occur by themselves or with any of the other conditions. Check for nitrates in effluent. Web this document introduces the activated sludge process control and troubleshooting chart methodology developed by the ohio epa compliance assistance unit. Chapter 9 sludge process simulators. Web a detailed review of how to use the activated sludge process control and troubleshooting manual and flow chart to solve noncompliance at smaller mechanical wastewater treatment plants was. Slower growth = slower removal rates. The object is to aprovide oxygen for organisms or bacteria to grow and reduce the organic waste (bod) in the wastewater. Web a detailed review of how to use the activated sludge process control and troubleshooting manual and flow chart to solve noncompliance at smaller mechanical wastewater treatment plants was provided. Identifying and mitigating. Stated in fundamental terms, the activated sludge process simply involves bringing together wastewater and a mixture of microorganisms under aerobic conditions. The methodology provides a simplified approach for operators to understand, control, and troubleshoot the activated sludge process using basic sampling and analysis. Web basic activated sludge carbon chemistry.29 biochemical oxygen demand (bod) and chemical oxygen demand (cod).29 Web view. Part ii settleability problems and loss of solids. • if the aeration tank effluent ammonia concentration is > 1 mg/l, then a condition exists in the aeration tank that is limiting complete conversion of the influent waste into bacterial cells. Stated in fundamental terms, the activated sludge process simply involves bringing together wastewater and a mixture of microorganisms under aerobic. Part ii settleability problems and loss of solids. Chapter 8 advanced concepts in nutrient removal. Web to solve a problem using guidelines and procedures: Chapter 9 sludge process simulators. Web basic activated sludge carbon chemistry.29 biochemical oxygen demand (bod) and chemical oxygen demand (cod).29 Water temperature < 10 c. Water temperature impacts growth rate. Web a detailed review of how to use the activated sludge process control and troubleshooting manual and flow chart to solve noncompliance at smaller mechanical wastewater treatment plants was provided. Increase capacity or decrease loading box 14. Web chapter 7 process troubleshooting. Increase capacity or decrease loading box 14. Web basic activated sludge carbon chemistry.29 biochemical oxygen demand (bod) and chemical oxygen demand (cod).29 Check chlorine demand (an increase in. Any of these can occur by themselves or with any of the other conditions. Settleometer < 80% in 5 minutes. 1) identify the problem, 2) determine the most likely cause and 3) consider suggested remedies or corrective measures. Web these “notes on activated sludge process control” are organized to answer these five questions. Settleometer < 80% in 5 minutes. Web basic activated sludge carbon chemistry.29 biochemical oxygen demand (bod) and chemical oxygen demand (cod).29 The object is to aprovide oxygen. 1) identify the problem, 2) determine the most likely cause and 3) consider suggested remedies or corrective measures. Web these “notes on activated sludge process control” are organized to answer these five questions. Check for nitrates in effluent. Chapter 9 sludge process simulators. Web chapter 7 process troubleshooting. Any of these can occur by themselves or with any of the other conditions. Central states water environment association may, 2013. Settleometer < 80% in 5 minutes. Web begin with box 1: This webinar provided specific instructions on how to perform process control like a pro (or like the cau). Web view sludge under microscope to identify filaments. Check for nitrates in effluent. • if the aeration tank effluent ammonia concentration is > 1 mg/l, then a condition exists in the aeration tank that is limiting complete conversion of the influent waste into bacterial cells. Identifying and mitigating impacts of drought conditions. Stated in fundamental terms, the activated sludge process simply involves bringing together wastewater and a mixture of microorganisms under aerobic conditions. Web these “notes on activated sludge process control” are organized to answer these five questions. Slower growth = slower removal rates. Web the best approach to troubleshooting the activated sludge process is based on microscopic examination and oxygen uptake rate (our) testing to determine the basic cause of the problem or upset and whether it is microbiological in nature. Denitrification is likely if nitrates exceed 10 mg/l. The methodology provides a simplified approach for operators to understand, control, and troubleshoot the activated sludge process using basic sampling and analysis. The methodology aims to give new operators an easy to understand foundation for operating and troubleshooting the activated sludge process.

Activated Sludge Process Control Troubleshooting Chart Directions DocsLib

![Activated Sludge Troubleshooting Chart [PDF Document]](https://cdn.vdocuments.mx/img/1200x630/reader020/image/20191008/55cf9898550346d033989150.png?t=1596897131)

Activated Sludge Troubleshooting Chart [PDF Document]

(PDF) Activated Sludge Process Control and Troubleshooting Chart

Activated Sludge Troubleshooting Chart

_TSS.jpg)

Activated Sludge Troubleshooting Chart

ActivatedSludgeTroubleshootingChart (1).pdf Protozoa Organisms

Activated Sludge Process Control and Troubleshooting Chart PDF PDF

Table 3 from ACTIVATED SLUDGE MICROBIOLOGY PROBLEMS AND THEIR CONTROL

Activated Sludge Troubleshooting Chart

Activated Sludge Troubleshooting Chart

Chapter 9 Sludge Process Simulators.

1) Identify The Problem, 2) Determine The Most Likely Cause And 3) Consider Suggested Remedies Or Corrective Measures.

Measure At Effluent Water Temperature.

Web This Document Introduces The Activated Sludge Process Control And Troubleshooting Chart Methodology Developed By The Ohio Epa Compliance Assistance Unit.

Related Post: