6011 Welding Rod Amperage Chart

6011 Welding Rod Amperage Chart - Plus you'll get the most complete welding rod chart on the internet in pdf! Welding around this amperage should give good fusion, no sticking and not too much heat. The thicker the rod, the higher the amperage. Web e6011 welding rod size and amperage chart. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Like any other electrode, the 6011 comes in different sizes and the amperage settings would vary depending on the size. Web 6011 welding rod amperage & characteristics. Classification of 6011 welding electrodes. Choosing the correct welding electrode, often called a rod or stick, is a challenging part of stick welding. Here is a table showing the recommended welding rod sizes and amperage for e6011 welding rods: What are 6011 welding rods made of? Similar to 6010 but with ac capabilities. Is 6011 welding electrode ac or dc? Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. Base material for e6011 welding rods. For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Classification of 6011 welding electrodes. Both welding electrodes have a violent digging arc, they are fast freeze, all position rods, the slag is thin and flaky and the penetration is deep. Welding around this amperage should give good fusion, no sticking. Here is a table showing the recommended welding rod sizes and amperage for e6011 welding rods: This electrode is an excellent choice for shipbuilding and structural work, general purpose fabrication, galvanized steel work, and rail cars. Web our powerful calculator let's you easily determine which stick electrode you need. Strong welds on clean metal. Web a good starting point for. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. As a beginner, it is always important to check the recommended values while deciding the amperage setting to be used for a particular weld. Web a good starting point for setting your amperage is to choose an amperage in the exact middle. Web 6011 welding rod amperage & characteristics. Is 6011 welding electrode ac or dc? Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Web welding rods compared: Welding positions for e6011 welding rods. Amperage setting for 6011 welding rods. Web e6011 (e4311) welding rod amperage chart. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. E6010 and e6011 size and amperage chart. Understanding stick welding rod classification is essential in selecting the correct electrode for your welding needs. Classification of 6011 welding electrodes. Web you can use our electrode amperage chart to find out the correct amp range for a specific electrode and its thickness. Base material for e6011 welding rods. Welding around this amperage should give good fusion, no sticking and. Base material for e6011 welding rods. Web a good starting point for setting your amperage is to choose an amperage in the exact middle of the range for a horizontal fillet weld. Web pinnacle alloys e6011 is a cellulosic electrode with penetrating characteristics designed to handle coated steels. Web e6011 (e4311) welding rod amperage chart. Choosing the correct welding electrode,. Thus a 3/16 inch rod will require an amperage of between 140 to 210 amps. Similar to 6010 but with ac capabilities. Browse suggested weld parameter settings for stick welding. As a beginner, it is always important to check the recommended values while deciding the amperage setting to be used for a particular weld. Diameter (inches) diameter (mm) 6010/6011. Commonly used in structural welding. High deposition, only suitable for flat and horizontal welds. Web 6011 welding rod amperage & characteristics. Thus a 3/16 inch rod will require an amperage of between 140 to 210 amps. Web this electrode combines a strong arc force with fast solidification of weld metal, thereby permitting vertical or overhead as well as flat and. Web welding for beginners tips and techniques using the 6011 electrode or farmers rod is what this video shows two techniques on how to use the electrode 6011 otherwise known as farmers rod. Keep in mind that the amp can be so different from one manufacturer to another. Web e6011 (e4311) welding rod amperage chart. 6010 and 6011 are virtually the same rod. Base material for e6011 welding rods. Ansi/aws a5.1 & asme sfa 5.1 e6011. Commonly used in structural welding. What is 6011 welding rod. What are 6011 welding rods made of? Diameter of 6011 welding rods. Welding around this amperage should give good fusion, no sticking and not too much heat. It is used mainly for sheet metal welding and low silicon deposit application. For example, a 1/8″ 6011 rod would be 100a at its middle amperage. Similar to 6010 but with ac capabilities. Web this chart provides an overview of the most common stick welding rod sizes and their corresponding classifications. On the other hand, a 3/32 inch rod will require an amperage between 40 and 85 amps.

Welding Rod Amperage Chart Pdf

E6011 Welding Rod (Applications, Amperage Settings & Tips

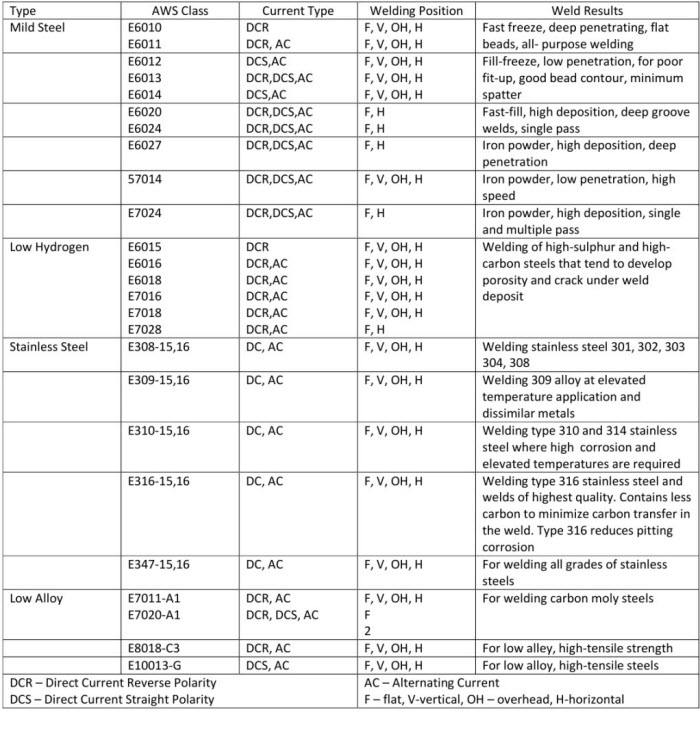

Arc Welding Rods Guide

Welding Rod Sizes Here's The Complete Guide

Welding Rod Amp Chart

6011 Welding Rod Amperage Chart

Tig Welding Amperage Chart

Welding Rod Amperage Chart Pdf

How Do I Calculate How Much Welding Rod I Need

What are a reasonable rods to use ? Welding Site

The Last Digit Tells You What Type Of Flux Coating Is On The Rod And What Kind Of Current You Can Use.

While Welding Overhead, The Amp Can Be Within 140 To 180.

E6011 (E4311) Electrode Can Be Run Easily With Low Current Due To Its Good Arc Start Ability.

Web The E6011 Welding Rod Is Suitable For Welding Of Mild Steels, Galvanized Steels And Certain Low Alloy Steels.

Related Post: