3D Printer Infill Pattern

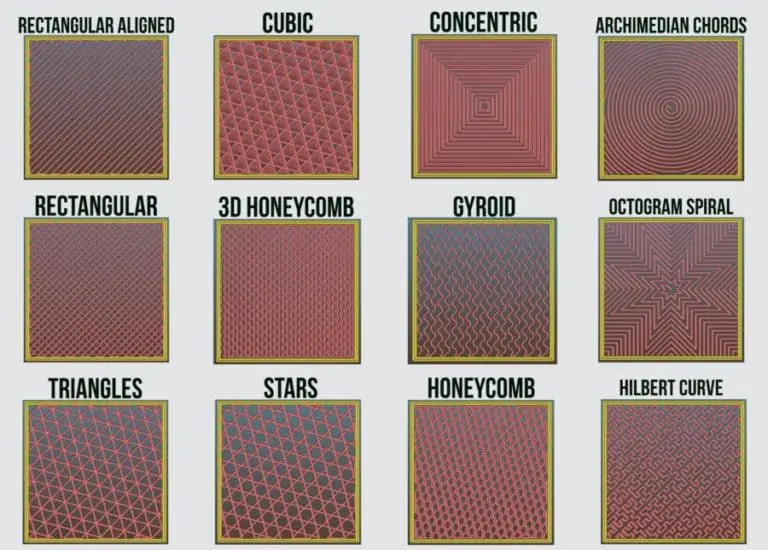

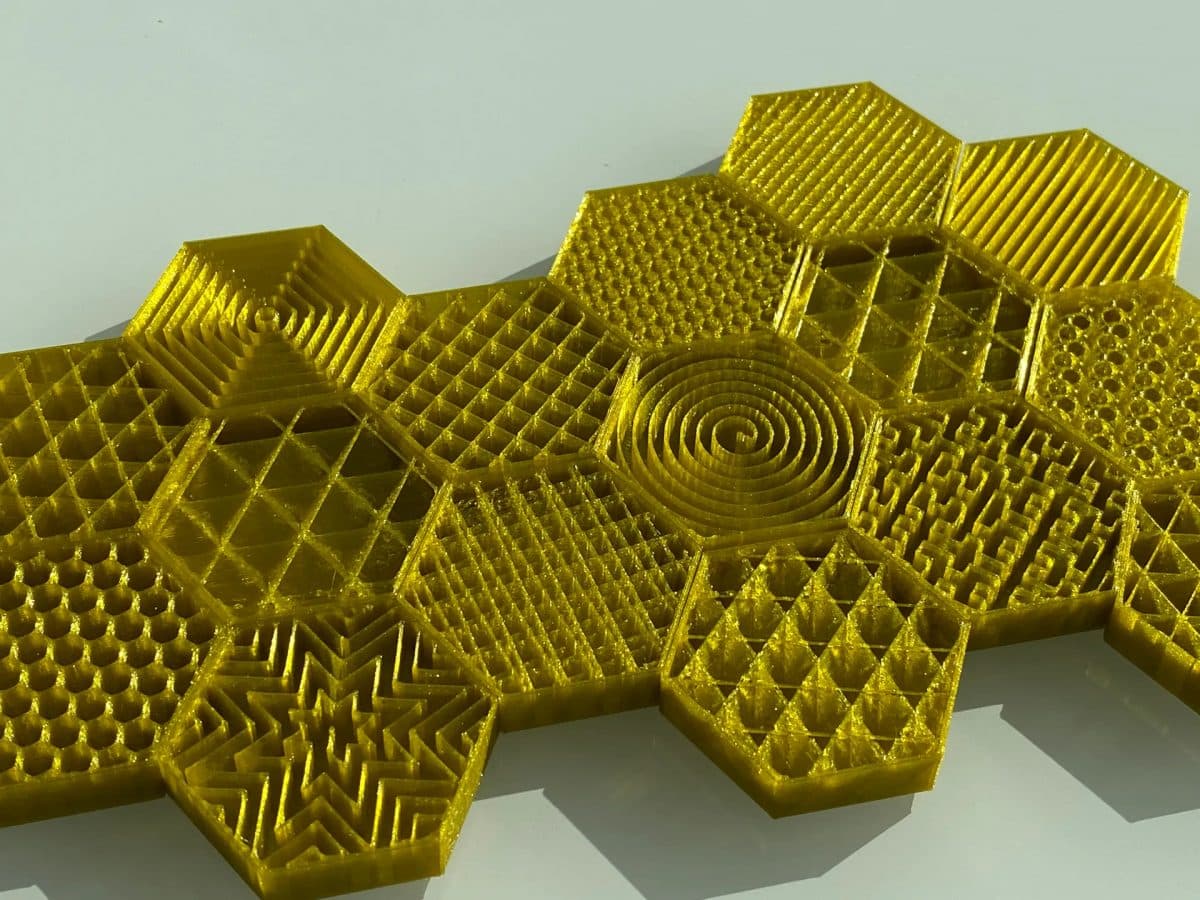

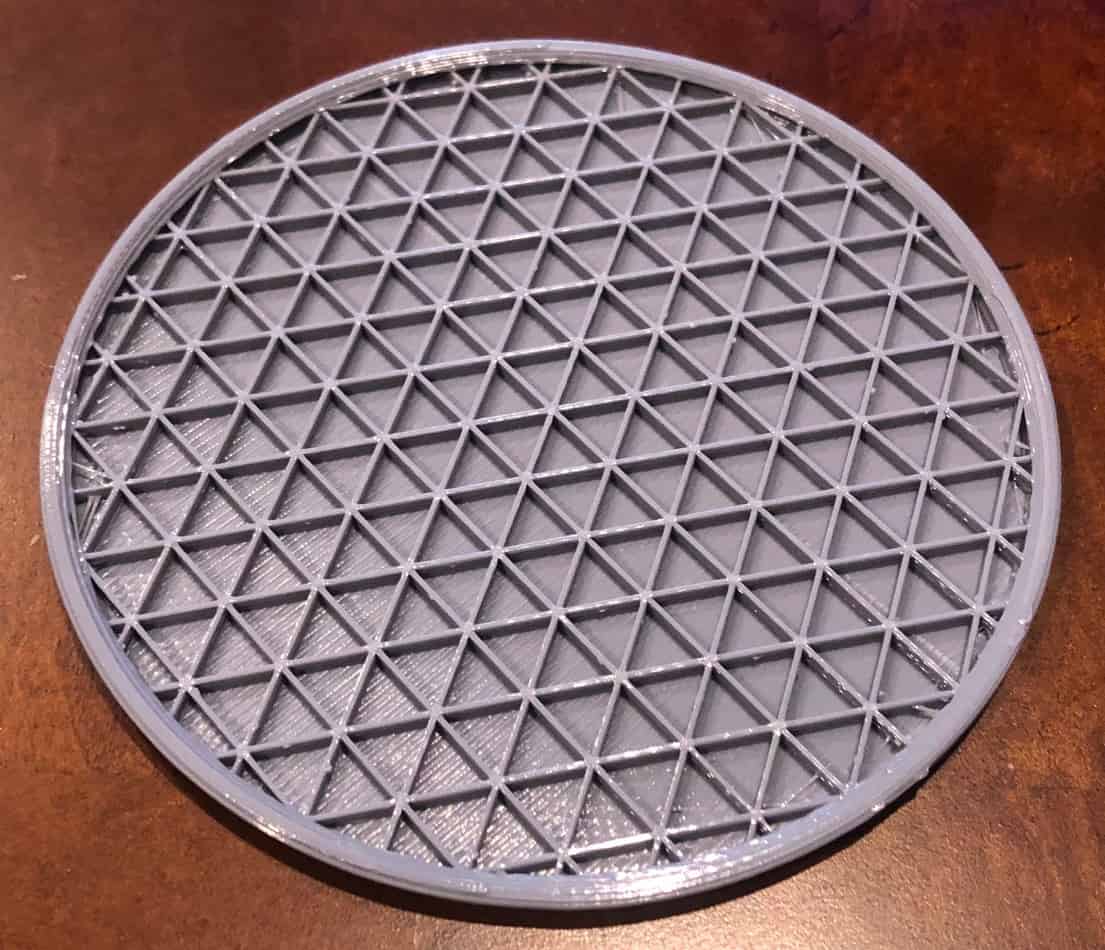

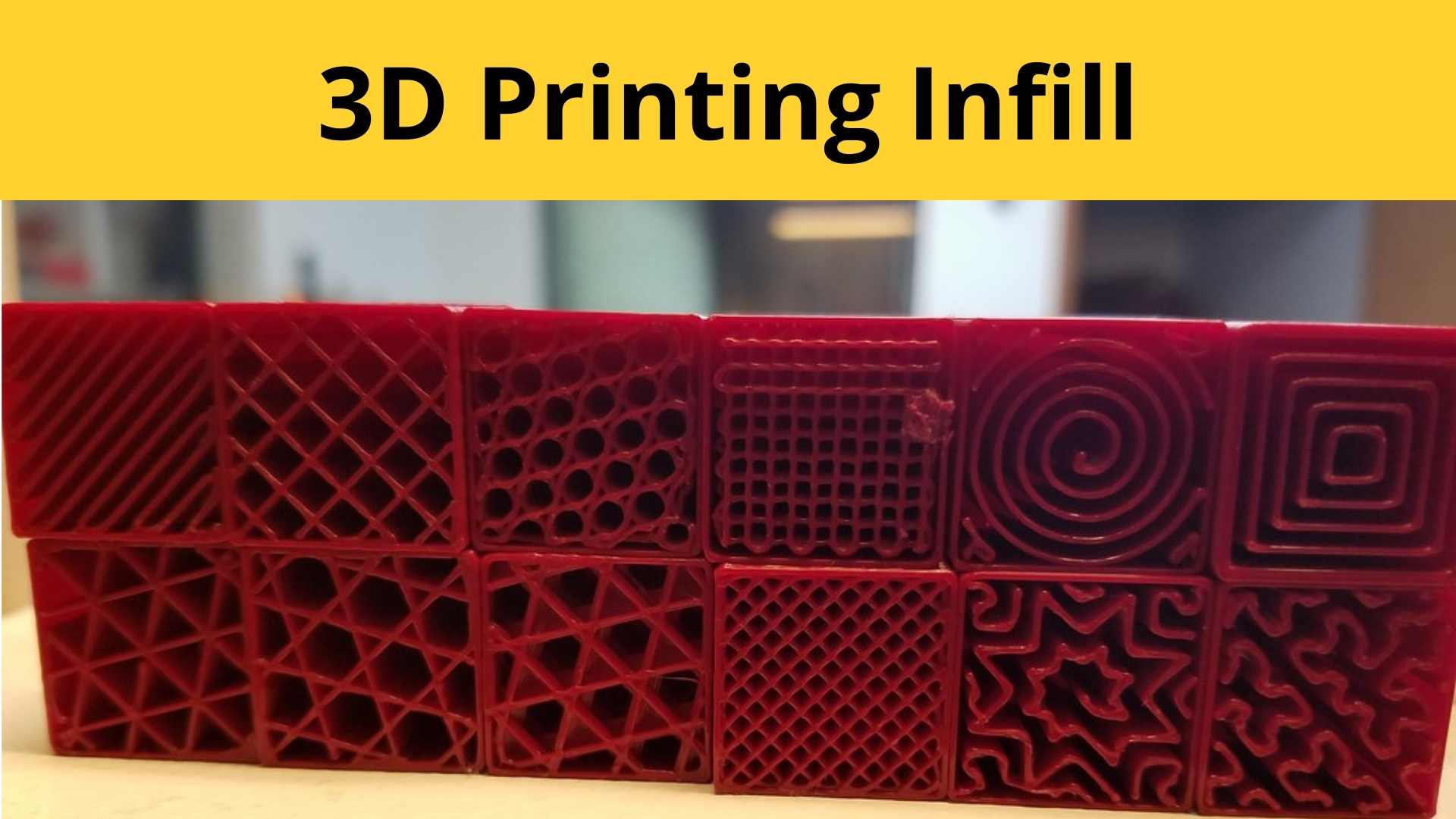

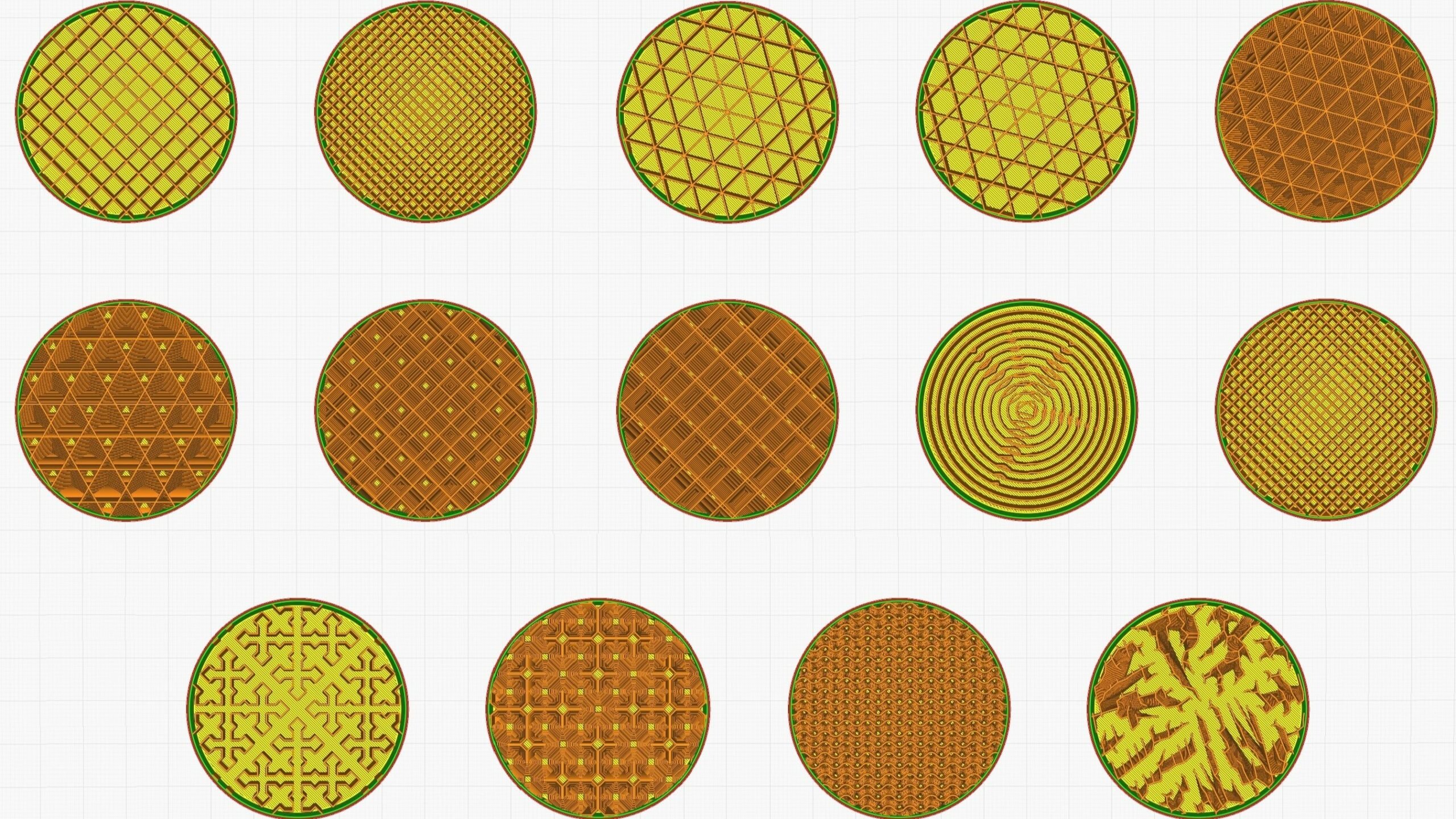

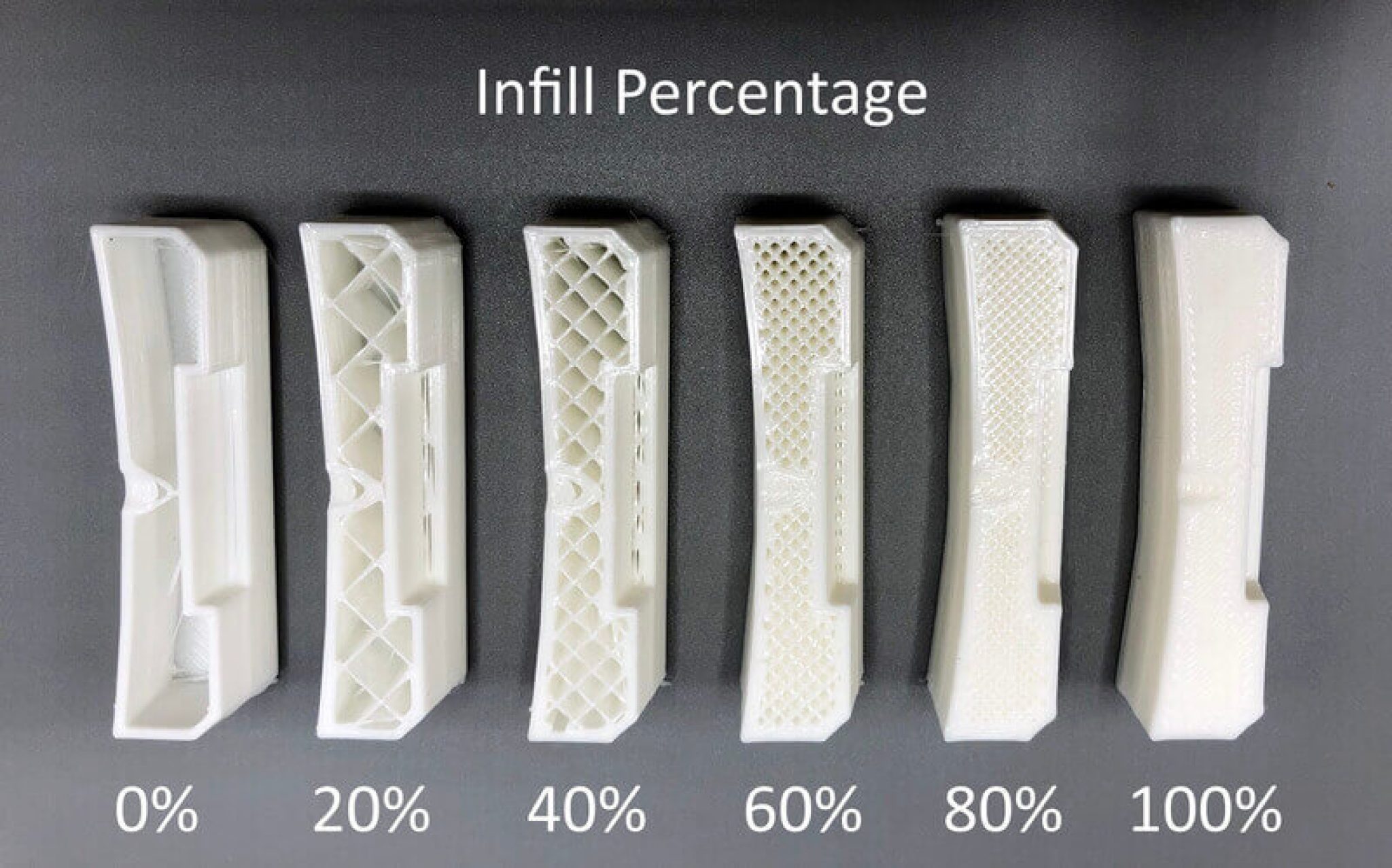

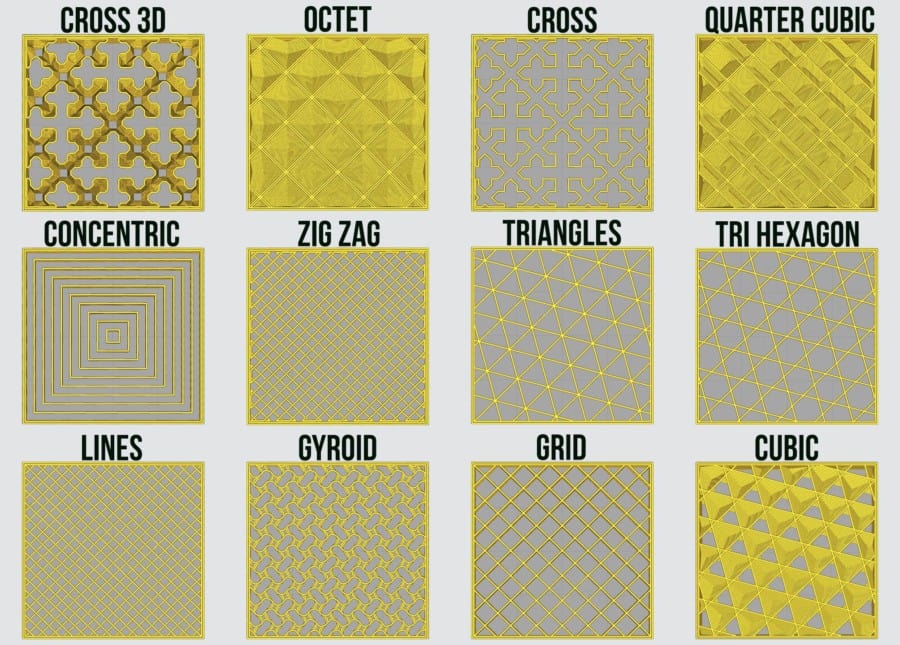

3D Printer Infill Pattern - Instead, we use a method that fills the inside of an object with a sparse supporting structure. Web the fastest 3d printing infill pattern is the concentric. When high strength in multiple directions is needed, choose the cubic, octet, or gyroid infill pattern. When you determine the function of your 3d printed part, the best infill pattern will vary. Web infill patterns conform to the interior structure of a 3d printed part and they have a significant effect on your part’s print time, filament consumption, flexibility, strength, weight, and what it can be used for. This does not mean that you need to compromise its mechanical characteristics. Along with the shell, the lower and upper layers, the infill is one of the four structural pillars of 3d printing. Web in 3d printing, infill plays an important role in a part's strength, structure, and weight. Web understanding the kind of load your 3d parts will have to withstand is critical in picking the best infill pattern. Web interactive model previews: Sliced models of most common infill patterns designed to hang on a string near your 3d printer(s) 5h 35m. When choosing an infill pattern, these are the main things to consider: To start, let’s explore what infill patterns are and why they matter. These standard designs can be selected in the 3d slicing software menu used to prepare parts for. Find the best cura infill patterns for your application. Along with the shell, the lower and upper layers, the infill is one of the four structural pillars of 3d printing. In this guide, i’ll explain the methods i use to choose the right infill percentage and patterns for my projects to maximize strength and cost savings. Web infill patterns define. Web infill 3d printing is a compromise between these two positions. Find the best cura infill patterns for your application. An infill density of 100% is a solid object, whereas 0% is a hollow object. Web the cubic infill pattern is the best infill pattern overall. Infill density refers to the amount of plastic inside a print. This infill pattern was first available on cura but is now available on multiple slicers, including prusaslicer and others. Web the cubic infill pattern is the best infill pattern overall. When you determine the function of your 3d printed part, the best infill pattern will vary. To start, let’s explore what infill patterns are and why they matter. Infill density. In this guide, i’ll explain the methods i use to choose the right infill percentage and patterns for my projects to maximize strength and cost savings. When high strength in multiple directions is needed, choose the cubic, octet, or gyroid infill pattern. This newly released infill is best for objects that don’t need great mechanical stability. Density per material used. There are patterns, however, that are incredibly common and that you can expect from any slicer software. Read on to learn more about it. Web infill patterns conform to the interior structure of a 3d printed part and they have a significant effect on your part’s print time, filament consumption, flexibility, strength, weight, and what it can be used for.. This pattern consists of only one line, with the lack of directional changes saving the printer time. Web interactive model previews: An infill density of 100% is a solid object, whereas 0% is a hollow object. Density per material used (better support for top layers with less material) visuals; Web 3d printed models are rarely printed solid (100% infill) or. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of. Web if you’re new to the world of 3d printing, you may be wondering what infill is for. Web 3d printed models are rarely printed solid (100% infill) or completely hollow. Consists of multiple parallel lines per layer, strengthening. When choosing an infill pattern, these are the main things to consider: Web many different infill patterns exist. Web the best infill pattern for 3d printing is a hexagonal shape such as cubic if you are after a good balance of speed and strength. Different patterns have varying impacts on print time, material usage, and part strength. To start, let’s. Web understanding the kind of load your 3d parts will have to withstand is critical in picking the best infill pattern. Web the fastest 3d printing infill pattern is the concentric. Best for general purpose use: Infill provides the 3d print with internal support as the printer builds each layer. Web the cubic infill pattern is the best infill pattern. Interactive model previews allow you to engage directly with your 3d models inside the 3dprinteros platform before committing to print. This pattern consists of only one line, with the lack of directional changes saving the printer time. For models that don’t need strength, lines and grid infill patterns are the. Without infill, printing the top layers would be very difficult , as the plastic would sag over the empty parts of. This infill pattern was first available on cura but is now available on multiple slicers, including prusaslicer and others. This article will define 3d printing infill, discuss how to select the correct infill pattern and density, and describe the various infill patterns. These standard designs can be selected in the 3d slicing software menu used to prepare parts for printing. What is infill in 3d printing? Here are the best infill pattern options for different 3d printing applications. Web the best infill pattern for 3d printing is a hexagonal shape such as cubic if you are after a good balance of speed and strength. Find the best cura infill patterns for your application. When high strength in multiple directions is needed, choose the cubic, octet, or gyroid infill pattern. Web 3d printed models are rarely printed solid (100% infill) or completely hollow. Web many different infill patterns exist. Sliced models of most common infill patterns designed to hang on a string near your 3d printer(s) 5h 35m. Čeština deutsch english español français italiano.

Understanding Infill Density Settings in 3D Printing 3DSourced

3D Print Infill Patterns Explained The 3D Bros

Best 3D Printing Infill Pattern Complete Details Inside

5 Strongest Infill Patterns Every 3D Print Slicer Should Have

Best 3D Printing Infill Pattern Complete Details Inside

Guide to 3D printing infill settings its pattern, percentage and

3D Printer Infill Patterns The Basics YouTube

Cura Guide to the Best Infill Patterns All3DP

Ultimate Beginner's Guide To 3D Printing Infill Pick 3D Printer

Guide about infill in 3D printing

Web The Fastest 3D Printing Infill Pattern Is The Concentric.

The Best Infill Patterns For Each Use & Filament Type.

Different Patterns Have Varying Impacts On Print Time, Material Usage, And Part Strength.

For Most 3D Prints, This Infill Is Not Visible.

Related Post: